لوحات/ طباقات

صاج

قضيب

أنابيب

2618A

ASTM B221 / AlCu2Mg1.5Ni / 2618A / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,10 - 0,25 |

| Manganese (Mn) | 0,00 - 0,25 |

| Magnesium (Mg) | 1,30 - 1,80 |

| Copper (Cu) | 1,90 - 2,70 |

| Titanium (Ti) | 0,04 - 0,10 |

| Iron (Fe) | 0,90 - 1,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Nickel (Ni) | 0,90 - 1,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.76 g/cm³ |

| Melting Point | 549 °C |

| Thermal Expansion | 21.6 µm/m°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 147 W/m.K |

| Electrical Resistivity | 37 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 350 MPa |

| Yield Strength | 420 MPa |

| Shear Strength | 260 MPa |

| Elongation A50 mm | %6 |

| Hardness | 120 HB |

2618A T6 aluminum alloy is known for its high strength, excellent thermal stability, and superior fatigue resistance. Composed of copper, magnesium, and silicon, this alloy is ideal for demanding applications requiring high-temperature performance. The T6 temper indicates that the alloy has undergone solution heat treatment followed by artificial aging, providing maximum strength and durability.

This alloy is widely used in aerospace, automotive, and defense industries for critical components. Common applications include jet engines, structural aerospace elements, engine pistons, and other high-temperature uses. 2618A T6 is compatible with anodizing, which enhances corrosion resistance by forming a protective oxide layer and offers an aesthetic finish. However, due to its high copper content, special care may be needed during the anodizing process. In terms of weldability, the alloy has limitations and often relies on mechanical fasteners or specialized welding techniques for joining.

Regarding forming and bending, 2618A T6 aluminum alloy offers limited formability due to its high strength. Careful handling and proper techniques are necessary for complex forming operations. Despite these challenges, the material’s fatigue resistance and mechanical stability make it highly reliable in high-vibration and dynamic load environments. These attributes make it a dependable choice for long-lasting and durable structures.

Corrosion resistance is naturally limited, especially in humid or corrosive environments, where additional surface protection treatments are recommended. Advantages of this alloy include high-temperature resistance, excellent fatigue resistance, and mechanical stability, while disadvantages include low corrosion resistance and limited formability. These features make 2618A T6 aluminum alloy an excellent choice for projects demanding lightweight materials and superior durability.

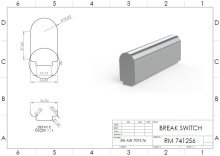

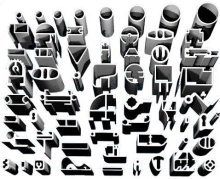

Extruded Round/Flat Bar, Forgings and Tubes per; 2618A T6, ASTM B221, UNS A92618, DTD 717, DTD 5084A, ISO AlCu2Mg1.5Ni, WNR 3.1924,

Choosing Factors for 2618A T6

- Strength: High

- Machining: Okay

- Weldability: Weak

- Formability: Okay

- Corrosion Resistance: Mediocre

- Heat Treating: Yes

Some Well-Known Applications for 2618A T6

In aircraft engines in the aerospace industry,

In autosports industry,

It has many areas of use, mainly in the defense industry.

- Round/Flat Bar

- Tube/Profile

حساب الوزن

حساب الوزن