Листы/Плиты

Лист

Бар/Листовая Сталь

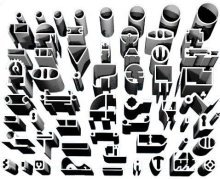

Трубы/Профили

7012

ASTM B221 / AlZn6Mg2Cu / 7012 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,15 |

| Chromium (Cr) | 0,00 - 0,04 |

| Manganese (Mn) | 0,08 - 0,15 |

| Magnesium (Mg) | 1,80 - 2,20 |

| Copper (Cu) | 0,80 - 1,20 |

| Titanium (Ti) | 0,02 - 0,08 |

| Iron (Fe) | 0,00 - 0,25 |

| Zinc (Zn) | 5,80 - 6,50 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 470 °C |

| Thermal Expansion | 23.2 µm/m.°C |

| Modulus of Elasticity | 71.1 GPa |

| Thermal Conductivity | 117 W/m.K |

| Electrical Resistivity | %31 IACS |

| Mechanical Properties | Value |

| Proof Strength | 540 MPa |

| Yield Strength | 580 MPa |

| Shear Strength | 354 MPa |

| Elongation A50 mm | %7 |

| Hardness | 150 HB |

The 7012 T6 aluminum alloy is known for its high mechanical strength, good corrosion resistance, and excellent machinability. It is commonly used in industries such as automotive, aerospace, defense, and construction. The T6 temper, achieved through heat treatment, provides the alloy with high tensile strength and hardness, making it ideal for heavy-load-bearing applications and environments that require high durability. Additionally, 7012 T6 is suitable for anodizing, which enhances its surface appearance and increases its corrosion resistance.

The weldability of 7012 T6 is good when the proper welding techniques are used. However, due to its high strength and hardness, special care is required during the welding process. In terms of bending, 7012 T6 is harder compared to the T4 temper, making the bending process more challenging. Nonetheless, with the right equipment and techniques, this alloy can be shaped into desired forms.

In terms of corrosion resistance, 7012 T6 performs exceptionally well, particularly against harsh environmental conditions such as seawater, making it ideal for maritime and outdoor structures. Additionally, 7012 T6 can be used in high-vibration environments, which makes it advantageous in dynamic industries such as aerospace, automotive, and defense. Its high durability and long-lasting performance enhance its reliability in these applications.

The advantages of 7012 T6 aluminum alloy include high mechanical strength, corrosion resistance, anodizing compatibility, weldability, and suitability for high-vibration environments. However, its high hardness can create challenges in welding and bending processes. Additionally, this alloy may not be as easy to machine as more flexible alloys. Despite these drawbacks, 7012 T6 is an excellent choice for industrial applications that require high performance and durability.

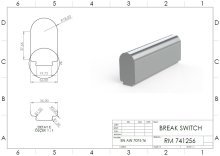

Cold Drawn Round/Flat Bars per; 7012 T6, ISO AlZn6Mg2Cu, ASTM B211, UNS A97012

Extruded Round/Flat Bar and Tubes per; 7012 T6, ISO AlZn6Mg2Cu, ASTM B221, UNS A97012

Choosing Factors for 7012 T6

- Strength: Medium

- Machining: Very good

- Weldability: Satisfactory

- Formability: Moderate

- Corrosion Resistance: Poor

- Heat Treating: Yes

Some Well-Known Applications for 7012 T6

It is used in limited structural applications in the aerospace industry where complex and high machinability feature is required.

SUPPLIED FORMS

- Round/Flat Bar

- Tube/Profile

Калькулятор Веса

Калькулятор Веса