Листы/Плиты

Лист

Бар/Листовая Сталь

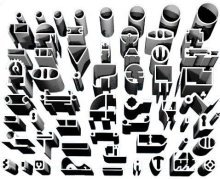

Трубы/Профили

5086

AMS QQ-A-200/5 / AlMg4 / 5086 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,05 - 0,25 |

| Manganese (Mn) | 0,20 - 0,70 |

| Magnesium (Mg) | 3,50 - 4,50 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,66 g/cm³ |

| Melting Point | 585 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 125 W/m.K |

| Electrical Resistivity | 29% IACS |

| Mechanical Properties | Value |

| Proof Strength | 117 MPa |

| Yield Strength | 262 MPa |

| Shear Strength | 159 MPa |

| Elongation A50 mm | 16% |

| Hardness | 70 HB |

The 5086 O aluminum alloy is known for its excellent corrosion resistance, good machinability, and solid mechanical properties. The O temper represents the softest form of the alloy, making 5086 O highly flexible and easy to process. These characteristics make 5086 O ideal for applications in harsh environmental conditions such as maritime, automotive, construction, and other outdoor uses. Additionally, 5086 O is suitable for anodizing, which enhances its surface appearance while increasing its corrosion resistance.

In terms of weldability, 5086 O aluminum alloy can be welded exceptionally well. Its soft structure facilitates easy welding, creating strong bonds. The alloy is also well-suited for bending, as its low hardness makes it easy to bend and shape. This makes 5086 O highly versatile, especially for projects that require bending and shaping.

In terms of corrosion resistance, 5086 O performs exceptionally well in harsh environments, such as seawater and humid conditions. This makes it ideal for the maritime industry and outdoor structures exposed to corrosive conditions. Additionally, 5086 O is also suitable for high-vibration environments, making it advantageous in industries such as automotive, aerospace, and defense. Its high durability and long-lasting performance enhance the reliability of 5086 O in these demanding applications.

The advantages of 5086 O aluminum alloy include excellent corrosion resistance, easy machinability, anodizing compatibility, weldability, and bending properties. However, its lower strength and durability may limit its use in applications requiring heavy load-bearing capabilities. Moreover, 5086 O may not be suitable for some high-performance durability requirements. Despite these drawbacks, 5086 O is an excellent choice for lightweight structures and applications where aesthetic appearance and corrosion resistance are crucial.

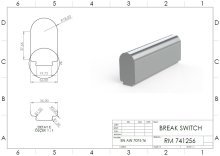

As Plate/Sheet; 5086 O, AMS QQ-A-250/7, ASTM B209, ISO AlMg4, DIN AlMg4Mn UNS A95086, ASTM B632, ASTM B928, AMS QQ-A-250/19, WNR 3.354

As Extrusion Rod, Flat Bar, Wire; 5086 O, ASTM B221, UNS A95086, ASTM B928, WNR 3.3545, AMS QQ-A-200/5

As Extruded Seamless Tube: 5086 O, WWW-T-700/5, ISO AlMg4, DIN AlMg4Mn UNS A95086, ASTM B241, WNR 3.3545

Choosing Factors for 5086 O

- Strength: Very good

- Machining: Good

- Weldability: Excellent

- Formability: Good

- Corrosion Resistance: Very good

- Heat Treating: Yes

Some Well-Known Applications for 5086 O

As a structural component of ship bridges and boats

As marine materials component,

In applications against corrosion,

It is used in TV and communication towers and in the defense industry.

- Plate

- Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

Калькулятор Веса

Калькулятор Веса