2017

UNS A92017 / AlCu4MgSi / 2017 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,0 |

| Magnesium (Mg) | 0,40 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.79 g/cm³ |

| Melting Point | 510 °C |

| Thermal Expansion | 22.9 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | 38 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 76 MPa |

| Yield Strength | 190 MPa |

| Shear Strength | 130 MPa |

| Elongation A50 mm | %15 |

| Hardness | 45 HB |

The 2017 O aluminum alloy is known for its excellent machinability, good corrosion resistance, and light weight. The O temper represents the softest form of the alloy, making 2017 O highly formable and machinable. As a result, 2017 O is ideal for various industrial applications, including automotive, aerospace, construction, and general engineering. Additionally, 2017 O aluminum is suitable for anodizing, which enhances its surface appearance and increases its corrosion resistance.

In terms of weldability, 2017 O aluminum alloy is highly weldable. The alloy's soft structure makes the welding process easier and ensures strong, reliable connections. This feature makes 2017 O suitable for a wide range of structural applications. Regarding bending, 2017 O is highly flexible and can be easily bent to form various shapes, making it ideal for shaping processes.

In terms of corrosion resistance, 2017 O performs well under atmospheric conditions, but its resistance to more aggressive environments like seawater is limited. Therefore, more corrosion-resistant alloys may be preferred for marine applications. When used in high-vibration environments, 2017 O's low mechanical strength may limit its performance, making it less suitable for applications that require high strength under dynamic conditions.

The advantages of 2017 O aluminum alloy include high machinability, anodizing compatibility, weldability, and ease of bending. However, its low mechanical strength and limited corrosion resistance may limit its use in challenging environments. Additionally, it may experience performance degradation in high-vibration settings. Despite these drawbacks, 2017 O is an excellent choice for lightweight applications and aesthetic purposes.

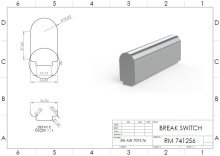

As Sheet/Plate; 2017 O, ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1

As Extruded Round/Flat Bar; 2017 O, AMS QQ-A-200/2, ASTM B221, UNS A92017, WNR 3.1325, DIN AlCuMg1

As Cold Drawn Round/Flat Bar: 2017 O, AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316,

Choosing Factors for 2017 O

- Strength: Moderate

- Machining: Excellent

- Weldability: Average

- Formability: Good

- Corrosion Resistance: Fair

- Heat Treating: Yes

Some Well-Known Applications for 2017 O

It is used in hydraulic applications, rivets,

In military vehicles and materials,

It is also used in automatic screwing machines.

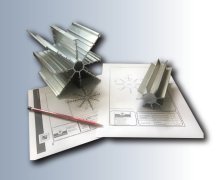

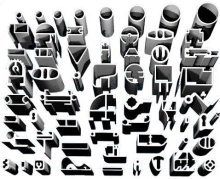

- Plate/Sheet

- Rod / Round Bar / Flat Bar

- Tube/Profile

حساب الوزن

حساب الوزن