7178

AMS QQ-A-200/13 / AlZn7MgCu / 7178 / T73511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,40 - 3,10 |

| Copper (Cu) | 1,60 - 2,40 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 6,30 - 7,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,83 g/cm³ |

| Melting Point | 477 °C |

| Thermal Expansion | 23.5 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | 31 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 503 MPa |

| Yield Strength | 572 MPa |

| Shear Strength | 340 MPa |

| Elongation A50 mm | 11% |

| Hardness | 152 HB |

سبيكة الألمنيوم 7178 T73511 معروفة بقوتها العالية ومقاومتها الممتازة للتآكل. تمثل المعالجة الحرارية T73511 شكلاً مُعالجًا للسبائك يمنحها صلابة ومتانة استثنائية. هذه الخصائص تجعل 7178 T73511 مثالية للاستخدام في التطبيقات المتطلبة مثل صناعة الطيران والفضاء والدفاع وغيرها من القطاعات عالية الأداء. بالإضافة إلى ذلك، يمكن أن يتم تحضير 7178 T73511 للأكسدة، مما يحسن مظهر سطحها ويزيد مقاومتها للتآكل، مما يجعلها مناسبة للتطبيقات الخارجية والبحرية.

من حيث القابلية للحام، يمكن لحام سبيكة الألمنيوم 7178 T73511، ولكن بسبب قوتها العالية، قد تكون عملية اللحام صعبة. يمكن تحقيق وصلات لحام قوية وموثوقة باستخدام تقنيات اللحام المناسبة والمعالجة الحرارية. فيما يتعلق بالانحناء، فإن الألمنيوم 7178 T73511 أصعب في الانحناء بسبب صلابته العالية، ولكنه يمكن تشكيله باستخدام المعدات والتقنيات المناسبة، مما يجعله مناسبًا للتطبيقات الهيكلية.

مقاومة التآكل لـ 7178 T73511 ممتازة، خاصة في الظروف الجوية والبيئات مثل مياه البحر، مما يجعله مثاليًا للاستخدام في التطبيقات البحرية والهياكل الخارجية. بالإضافة إلى ذلك، يمكن استخدام سبيكة الألمنيوم 7178 T73511 في البيئات ذات الاهتزاز العالي، مما يجعلها مفيدة في صناعات مثل السيارات والطيران والدفاع. تزيد متانته العالية وأداؤه طويل الأمد من موثوقيته في هذه التطبيقات الديناميكية.

تشمل مزايا سبيكة الألمنيوم 7178 T73511 القوة الميكانيكية العالية، ومقاومة التآكل الممتازة، والتوافق مع الأكسدة، والقابلية للحام، والملاءمة للبيئات عالية الاهتزاز. ومع ذلك، تتطلب صلابته العالية التعامل بحذر أثناء عمليات الانحناء واللحام. بالإضافة إلى ذلك، قد يكون من الأصعب تصنيع هذه السبائك مقارنة بالسبائك الأكثر ليونة. على الرغم من هذه التحديات، فإن 7178 T73511 يعد خيارًا ممتازًا للتطبيقات الصناعية التي تتطلب أداءً عاليًا ومتانة.

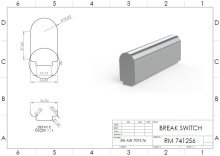

كقضبان مستديرة/مسطحة مسحوبة، أسلاك وأنابيب; 7178 T73511، ASTM B221، AMS QQ-A-200/13، UNS A97178، ISO AlZn7MgCu

عوامل اختيار 7178 T73511

- القوة: جيدة جدًا

- سهولة التشغيل: منخفضة

- القابلية للحام: متوسطة

- القابلية للتشكيل: جيدة

- مقاومة التآكل: مقبولة

- المعالجة الحرارية: نعم

بعض التطبيقات المعروفة لـ 7178 T73511

في هياكل الهبوط للطائرات،

في جسم الطائرة،

يتم استخدامه بشكل أساسي في صناعة الطيران، ولكنه يستخدم أيضًا في قطاعي البناء والسيارات.

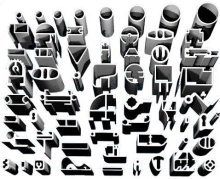

- قضيب / قضيب مستدير / قضيب مسطح

- أنبوب/بروفيل

حساب الوزن

حساب الوزن