2219

UNS A92219 / AlCu6Mn / 2219 / T3

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,00 - 0,15 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 1,00 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.84 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22 µm/m.°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | 44% IACS |

| 机械性能 | 值 |

| Proof Strength | 220 MPa |

| Yield Strength | 330 MPa |

| Shear Strength | 200 MPa |

| Elongation A50 mm | 13% |

| Hardness | 100 HB |

2219 T3 铝合金以其高机械强度、优异的焊接性能和良好的耐腐蚀性而闻名。通过热处理获得的 T3 状态赋予该合金更高的耐用性和硬度。这些特性使 2219 T3 成为高性能结构应用的理想选择,特别是在航空航天、太空及其他高要求行业。此外,2219 T3 铝合金适合阳极氧化处理,从而提升表面外观并增强耐腐蚀性。

在焊接方面,2219 T3 铝合金表现优异。合金的高强度和耐久性使焊接过程更加顺利,能够获得强固可靠的接头。然而,为确保最佳效果,必须采用适当的热处理和焊接技术。关于弯曲,由于 2219 T3 的高硬度,相较于更柔韧的合金,弯曲可能更具挑战性,但使用正确的设备和技术仍可成形,使其在结构应用中非常有用。

2219 T3 的耐腐蚀性优异,尤其是在大气环境中,并且对如海水等腐蚀环境具有良好抵抗能力。这使得 2219 T3 成为海洋及户外应用的理想选择。此外,2219 T3 铝合金适用于高振动环境,在汽车、航空航天和国防等行业具有优势。其高耐久性和长期性能进一步增强了其在高要求应用中的可靠性。

2219 T3 铝合金的优点包括高机械强度、耐腐蚀性、优异的焊接性能、适合阳极氧化处理以及适用于高振动环境。然而,其高硬度在弯曲和成型过程中需要谨慎操作。此外,该合金的可加工性可能不如更柔韧的合金。尽管存在这些挑战,2219 T3 仍是需要高性能和耐久性的工业应用的优秀选择。

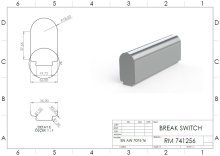

挤压材 圆棒/扁棒及管材: 2219 T3, ASTM B221, UNS A92219, ISO AlCu6Mn

板材/薄板; 2219 T3, ASTM B209, UNS A92219, AMS 4031, AMS QQ-A-250/30A, ISO AlCu6Mn

选择 2219 T3 的因素

- 强度: 高

- 加工性能: 较弱

- 焊接性: 非常好

- 成形性: 良好

- 耐腐蚀性: 满意

- 热处理: 是

2219 T3 的一些知名应用

作为工程应用中的结构构件,

通常用于航空航天工业,

也用于飞机材料及燃料箱。

- 圆棒 / 圆杆 / 扁棒

- 板材/薄板

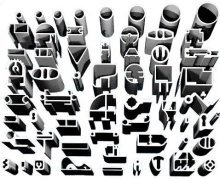

- 管材/型材

计算 重量计算

计算 重量计算