Cold Drawn Round Bar

Cold Drawn Tube

6082

Cold Drawn/Finished (CF) / AlMgSi1 / AlSi1MgMn (Soğuk Çekim) / 6082 / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,70 - 1,30 |

| Chromium (Cr) | 0,00 - 0,25 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.71 g/cm³ |

| Melting Point | 575 °C |

| Thermal Expansion | 23.1 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 170 W/m.K |

| Electrical Resistivity | 42% IACS |

| Mechanical Properties | Value |

| Proof Strength | 120 MPa |

| Yield Strength | 205 MPa |

| Shear Strength | 126 MPa |

| Elongation A50 mm | %16 |

| Hardness | 58 HB |

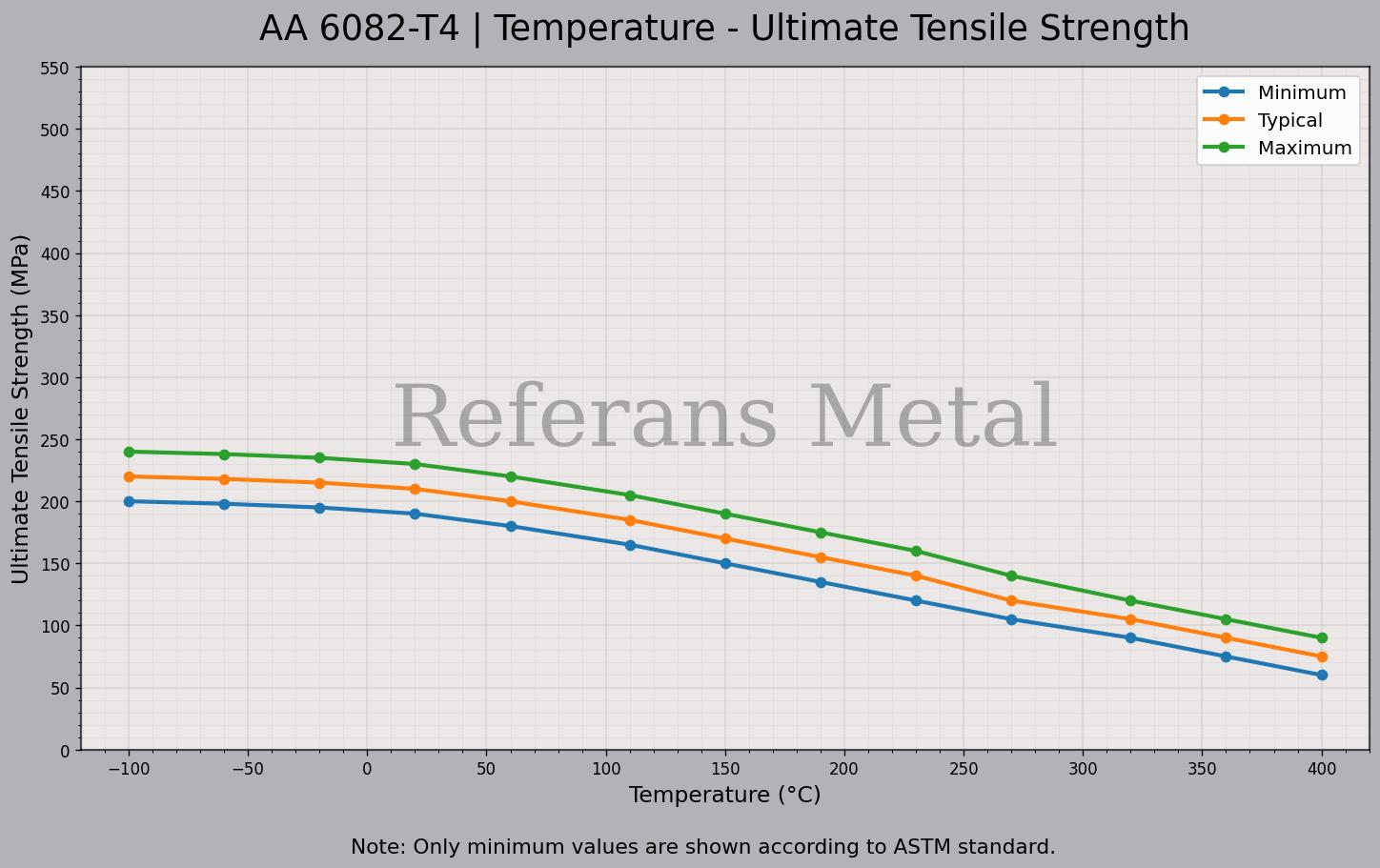

| 6082 T4 Temperature – Tensile Strength Graph |

|

6082 T4 aluminum alloy belongs to the Al-Mg-Si (6xxx series) group and offers a well-balanced combination of high strength and good corrosion resistance. The T4 temper condition refers to solution heat treatment followed by natural aging, which provides the material with good ductility and formability. 6082 T4 demonstrates satisfactory resistance to atmospheric conditions and many industrial environments. Its strength level is higher than that of 6063 alloy within the same series, making it a preferred choice for load-bearing and semi-structural applications.

.png) In terms of machinability, 6082 T4 exhibits stable and reliable performance in machining operations. Surface finish quality during cutting is generally good, and tool wear remains at manageable levels. Its bending and forming capability is significantly better than harder temper conditions such as T6. This allows the production of complex geometries and gives 6082 T4 a clear advantage over high-strength but difficult-to-form alloys such as 7075. In addition, its response to vibration is more damping compared to steel, and when combined with its low weight, this makes it suitable for machinery and structural applications.

In terms of machinability, 6082 T4 exhibits stable and reliable performance in machining operations. Surface finish quality during cutting is generally good, and tool wear remains at manageable levels. Its bending and forming capability is significantly better than harder temper conditions such as T6. This allows the production of complex geometries and gives 6082 T4 a clear advantage over high-strength but difficult-to-form alloys such as 7075. In addition, its response to vibration is more damping compared to steel, and when combined with its low weight, this makes it suitable for machinery and structural applications.

6082 T4 alloy is also favorable in terms of weldability. It can be readily joined using MIG and TIG welding methods, and no excessive loss of mechanical properties is observed after welding. This represents a significant advantage compared to 7075 alloy, which experiences more pronounced strength reduction after welding. Regarding surface finishing, 6082 T4 is suitable for anodizing and painting processes; however, the anodized surface appearance may be slightly duller and less uniform compared to 6063 alloy. Nevertheless, its surface performance remains sufficient for functional applications.

Due to these characteristics, 6082 T4 aluminum alloy is widely used in various sectors such as construction and structural profiles, bridges and platforms, transportation systems, automotive chassis components, rail systems, and general machinery manufacturing. While 5083 alloy is often preferred in marine applications due to its superior corrosion resistance, 6082 T4 offers better machinability and a more favorable cost-performance balance. Overall, 6082 T4 stands out as a versatile and reliable aluminum alloy that combines strength, formability, weldability, and economic efficiency.

MATERIAL COMPOSITION STANDARDS

6082 T4 can be produced according to the following standards:

• 6082 T4 Plate; ISO AlSi1MgMn, ASTM B209, UNS A96082, WNR 3.2315

• 6082 T4 Sheet; ISO AlSi1MgMn, ASTM B209, UNS A96082, WNR 3.2315

• 6082 T4 Cold Drawn Bar; ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315

• 6082 T4 Cold Drawn Beam; ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315

• 6082 T4 Cold Drawn Wire; ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315

• 6082 T4 Cold Drawn Tube; ISO AlSi1MgMn, ASTM B211, UNS A96082, WNR 3.2315

• 6082 T4 Extruded Bar; ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315

• 6082 T4 Extruded Beam; ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315

• 6082 T4 Extruded Wire; ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315

• 6082 T4 Extruded Tube; ISO AlSi1MgMn, ASTM B221, UNS A96082, WNR 3.2315

CHARACTERISTIC PROPERTIES OF 6082 T4:

- Strength: Very Good

- Machinability: Good

- Weldability: Medium (T6 heat treatment is recommended.)

- Formability: Excellent

- Corrosion Resistance: Above Average

- Heat Treatment: Yes

COMMON APPLICATIONS OF 6082 T4:

Structural materials under high stress,

Marine and boat applications,

Also used in bicycle manufacturing and machinery industry.

STOCK

We supply 6082 T4 in plate/sheet, sheet, bar/beam, and tube/profile forms.

- Plate / Sheet

- Sheet

- Bar / Beam

- Tube / Profile

Weight Calculator

Weight Calculator