2011

A-U5PbBi / AlCu6BiPb / 2011 / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,40 Max |

| Copper (Cu) | 5,00 - 6,00 |

| Lead (Pb) | 0,20 - 0,60 |

| Iron (Fe) | 0,70 Max |

| Zinc (Zn) | 0,00 - 0,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.82 g/cm³ |

| Melting Point | 540 °C |

| Thermal Expansion | 22,9 µm/m.°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | 39% IACS |

| Mechanical Properties | Value |

| Proof Strength | 140 MPa |

| Yield Strength | 310 MPa |

| Shear Strength | 190 MPa |

| Elongation A50 mm | %18 |

| Hardness | 70 HB |

The 2011 T4 aluminum alloy is known for its excellent machinability, low mechanical strength, and good corrosion resistance. The T4 temper, achieved through heat treatment, provides the alloy with increased hardness, but 2011 T4 still maintains high machinability characteristics. These properties make 2011 T4 ideal for applications in industries such as automotive, aerospace, electronics, and mechanical engineering. Additionally, 2011 T4 is suitable for anodizing, which enhances the surface appearance while increasing its corrosion resistance.

In terms of weldability, 2011 T4 aluminum alloy is generally weldable, but its low strength requires careful attention during the welding process. Proper heat treatment during welding is essential to maintain the alloy's properties. Regarding bending, 2011 T4 is highly suitable as it has high machinability and is easy to bend, making it ideal for various shaping processes.

In terms of corrosion resistance, 2011 T4 aluminum alloy performs well under atmospheric conditions, but its resistance to more aggressive environments, such as seawater, is limited. Therefore, for marine applications, more corrosion-resistant alloys may be preferred. Regarding its use in high-vibration environments, the lower mechanical strength of 2011 T4 may limit its use in such applications.

The advantages of 2011 T4 aluminum alloy include high machinability, ease of bending, anodizing compatibility, and good corrosion resistance. However, its low mechanical strength and limited corrosion resistance in harsh environments can be disadvantages. Additionally, its performance in high-vibration environments is not as strong as more durable alloys. Despite these limitations, 2011 T4 is an excellent choice for lightweight applications and aesthetic purposes.

Extruded Round/Flat Bar and Tubes per; 2011 T4, ASTM B221, UNS A92011, WNR 3.1655, ISO AlCu6BiPb, AFNOR A-U5PbBi, UNE L-3192, UNI 9002/5

Choosing Factors for 2011 T4

- Strength: Moderate

- Machining: Excellent

- Weldability: Poor

- Formability: Good

- Corrosion Resistance: Weak

- Heat Treating: Yes

Some Well-Known Applications for 2011 T4

Precision machine parts,

Automotive trims,

Tube stems and fittings.

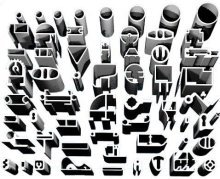

- Rod / Round Bar / Flat Bar

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Up to & incl. 60 | 125 | 275 | %14 |

Weight Calculator

Weight Calculator