Листы/Плиты

Лист

Бар/Листовая Сталь

Трубы/Профили

7178

ASTM B221 / AlZn7MgCu / 7178 / T6511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,40 - 3,10 |

| Copper (Cu) | 1,60 - 2,40 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 6,30 - 7,30 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,83 g/cm³ |

| Melting Point | 479 °C |

| Thermal Expansion | 23.5 x 10^-6 /K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | 31% IACS |

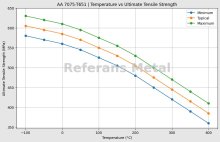

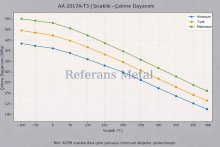

| Mechanical Properties | Value |

| Proof Strength | 560 MPa |

| Yield Strength | 630 MPa |

| Shear Strength | 370 MPa |

| Elongation A50 mm | 5% |

| Hardness | 160 HB |

Алюминиевый сплав 7178 T6511 известен своей высокой механической прочностью, хорошей коррозионной стойкостью и отличной обрабатываемостью. Закалка T6511 достигается термической обработкой, придавая сплаву высокую твердость и долговечность. Эти свойства делают 7178 T6511 идеальным выбором для высокопроизводительных применений, особенно в авиации, автомобильной промышленности, оборонной промышленности и других требовательных сферах. Кроме того, 7178 T6511 подходит для анодирования, что улучшает внешний вид поверхности и повышает коррозионную стойкость, обеспечивая долгосрочную работу в суровых условиях, таких как наружные и морские применения.

Свариваемость 7178 T6511 хорошая при использовании соответствующих методов сварки. Однако из-за высокой твердости и прочности сварочные работы требуют осторожности и квалификации. При гибке 7178 T6511 представляет трудности из-за повышенной твердости. Хотя сплав можно формовать с помощью подходящего оборудования и технологий, операции гибки требуют большей осторожности по сравнению с более пластичными сплавами.

Что касается коррозионной стойкости, 7178 T6511 показывает отличные результаты, особенно в суровых условиях, таких как морская вода. Это делает его идеальным для морских конструкций, наружных сооружений и других приложений, подверженных коррозии. Кроме того, 7178 T6511 подходит для использования в условиях высокой вибрации, что выгодно для авиационной, автомобильной и оборонной промышленности. Его высокая долговечность и продолжительный срок службы повышают надежность 7178 T6511 в этих сложных приложениях.

Преимущества алюминиевого сплава 7178 T6511 включают высокую механическую прочность, коррозионную стойкость, совместимость с анодированием, свариваемость и пригодность для условий высокой вибрации. Однако его высокая твердость и прочность могут создавать трудности при сварке и гибке. Кроме того, этот сплав может быть менее легко обрабатываемым, чем более пластичные сплавы. Несмотря на эти сложности, 7178 T6511 является отличным выбором для промышленных применений, требующих высокой производительности и долговечности.

7178 T6511 может быть поставлен в соответствии со следующими стандартами.

• 7178 T6511 Холоднотянутая прутка; UNS A97178, ASTM B211, ISO AlZn7MgCu, QQ-A-430

• 7178 T6511 Холоднотянутая полоса; UNS A97178, ASTM B211, ISO AlZn7MgCu, QQ-A-430

• 7178 T6511 Холоднотянутая проволока; UNS A97178, ASTM B211, ISO AlZn7MgCu, QQ-A-430

• 7178 T6511 Холоднотянутая труба; UNS A97178, ASTM B211, ISO AlZn7MgCu, QQ-A-430

• 7178 T6511 Экструзионный профиль; AMS QQ-A-200/13, ASTM B221, SAE J454, UNS A97178, ISO AlZn7MgCu

Факторы выбора для 7178 T6511

- Прочность: Отличная

- Обрабатываемость: Слабая

- Свариваемость: Средняя

- Формуемость: Средняя

- Коррозионная стойкость: Средняя

- Термическая обработка: Да

Некоторые известные применения 7178 T6511

Используется в тормозных колодках в автомобильной промышленности,

Также в авиационной промышленности,

Применяется в строительной отрасли.

- Труба/Профиль

- Круглый/Плоский пруток

Калькулятор Веса

Калькулятор Веса