板/板

钣金

棒条/金属板

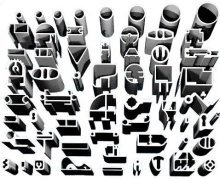

管道/型材

5154

AMS 4019 / AlMg3.5 / 5154 / H32

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,15 - 0,35 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 3,10 - 3,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2,66 g/cm³ |

| Melting Point | 595 °C |

| Thermal Expansion | 23.9 µm/m-°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 125 W/m.K |

| Electrical Resistivity | 32% IACS |

| 机械性能 | 值 |

| Proof Strength | 207 MPa |

| Yield Strength | 269 MPa |

| Shear Strength | 152 MPa |

| Elongation A50 mm | 14% |

| Hardness | 67 HB |

5154 H32 铝合金以其高耐腐蚀性、良好的加工性能和中等强度而闻名。该材料属于铝镁合金类别,广泛应用于航海、汽车、建筑及其他暴露于恶劣环境条件的工业领域。H32 状态通过热处理赋予合金中等硬度,既提高了耐用性,又保持了柔韧性。其轻质且坚固的结构使其成为户外应用以及需要防水、防盐和防潮组件的理想选择。

5154 H32 铝合金非常适合阳极氧化处理。阳极氧化在合金表面形成保护性氧化层,提高了耐腐蚀性,同时赋予美观的外观。此特性尤其适用于航海和户外应用。在焊接性能方面,该合金表现良好。作为铝镁合金,使用合适的焊接技术可实现牢固可靠的焊接接头。

在弯曲和成形方面,5154 H32 铝合金具有较高的柔韧性和良好的加工性能。尽管经过冷加工,但通过正确的加工方法,合金易于成形和弯曲。这使其在汽车和建筑行业中能够制造复杂形状。此外,5154 H32 合金还可安全应用于高振动环境。凭借其高耐久性和弹性模量,可用于制造抗振动组件。

在耐腐蚀性能方面,5154 H32 铝合金对海水、湿气及大气环境表现出较强的耐受性。这使得该合金成为航海和潮湿环境设备的理想材料。其优点包括高耐腐蚀性、良好加工性和轻质,而缺点则是对高温的耐受有限及在某些强度应用中的性能受限。

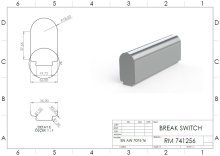

材料成分标准

5154 H32 可符合以下标准。

板材/薄板形式; 5154 H32,ISO AlMg3.5,DIN AlMg3,WNR 3.3535,UNS A95154,ASTM B209,AMS 4019

5154 H32 的主要特性:

- 强度:中等

- 加工性能:适中

- 焊接性能:适中

- 成形性:良好

- 耐腐蚀性:优异

- 热处理:无

5154 H32 的一些常见应用:

航海材料,

车辆底盘和车身,

还用于饮料罐制造。

库存

我们生产并供应以板材/薄板形式的 5154 H32。

- 板材

- 薄板

计算 重量计算

计算 重量计算