Cold Drawn Round Bar

Cold Drawn Tube

2017

Cold Drawn/Finished (CF) / AlCu4MgSi (Soğuk Çekim) / 2017 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,80 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,0 |

| Magnesium (Mg) | 0,40 - 1,00 |

| Copper (Cu) | 3,50 - 4,50 |

| Titanium (Ti) | 0,00 - 0,25 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.79 g/cm³ |

| Melting Point | 513 °C |

| Thermal Expansion | 23.6 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 134 W/m.K |

| Electrical Resistivity | 38 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 270 MPa |

| Yield Strength | 390 MPa |

| Shear Strength | 262 MPa |

| Elongation A50 mm | 16% |

| Hardness | 105 HB |

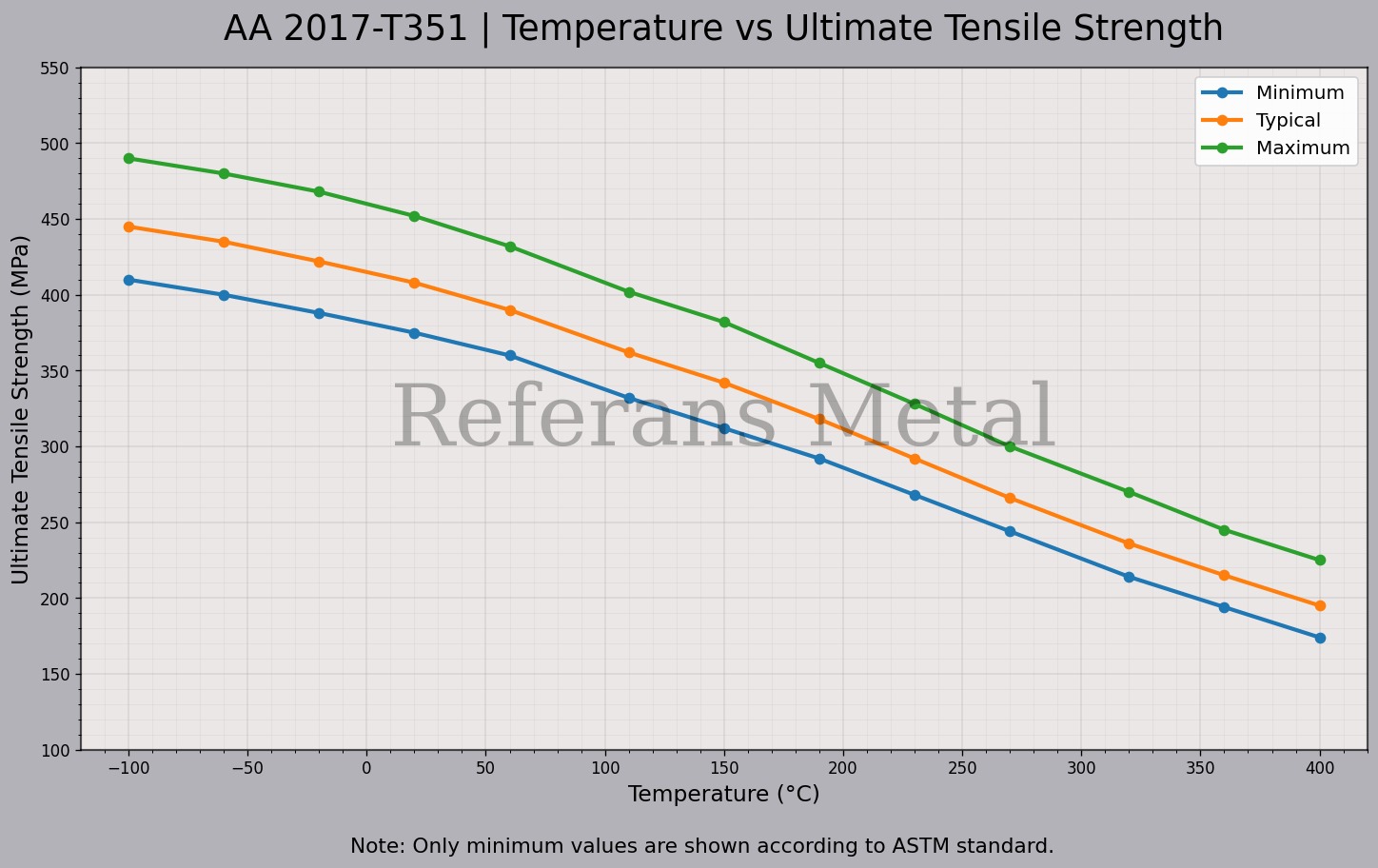

| 2017 T351 Temperature – Ultimate Tensile Strength Graph |

|

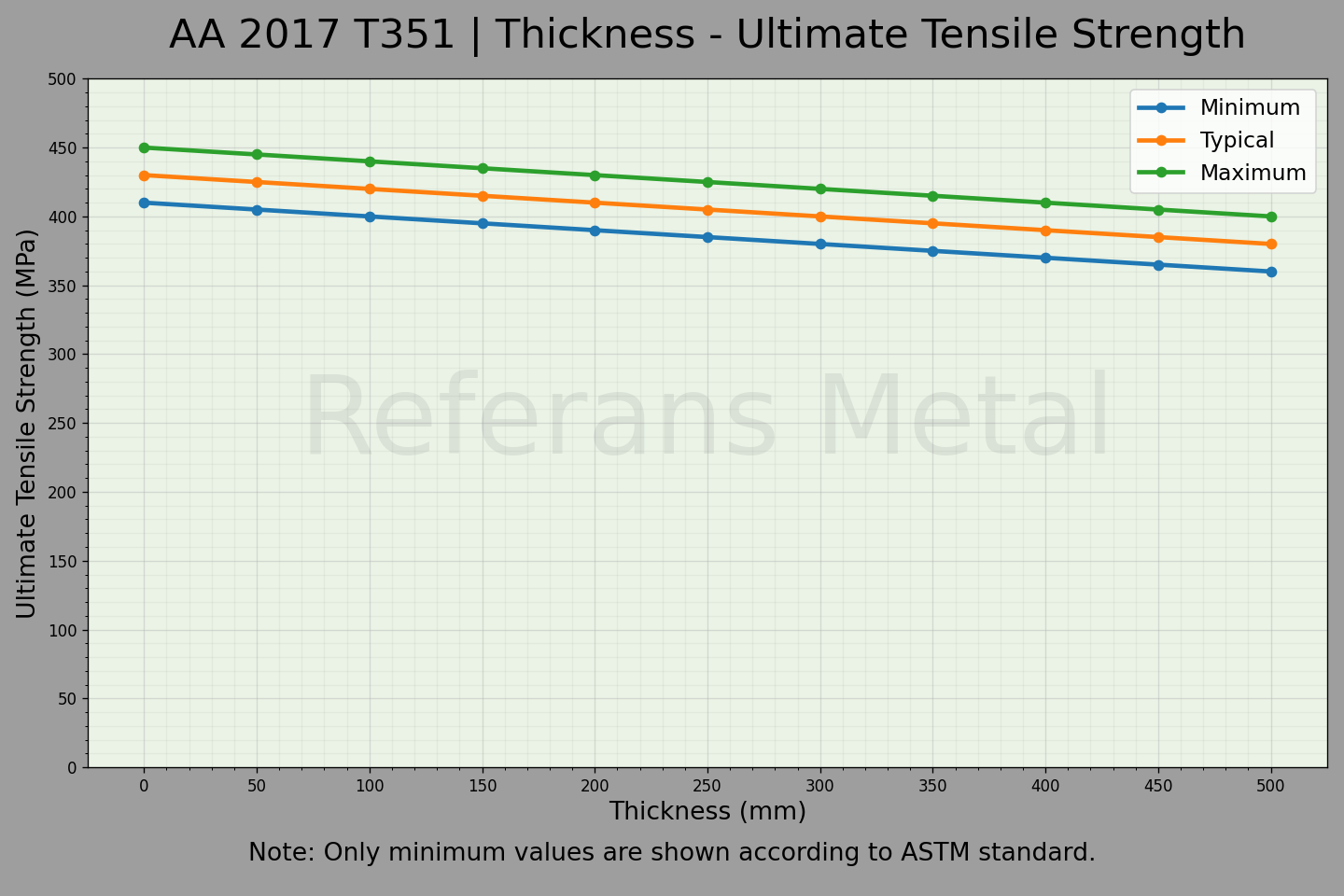

| 2017 T351 Thickness – Ultimate Tensile Strength Graph |

|

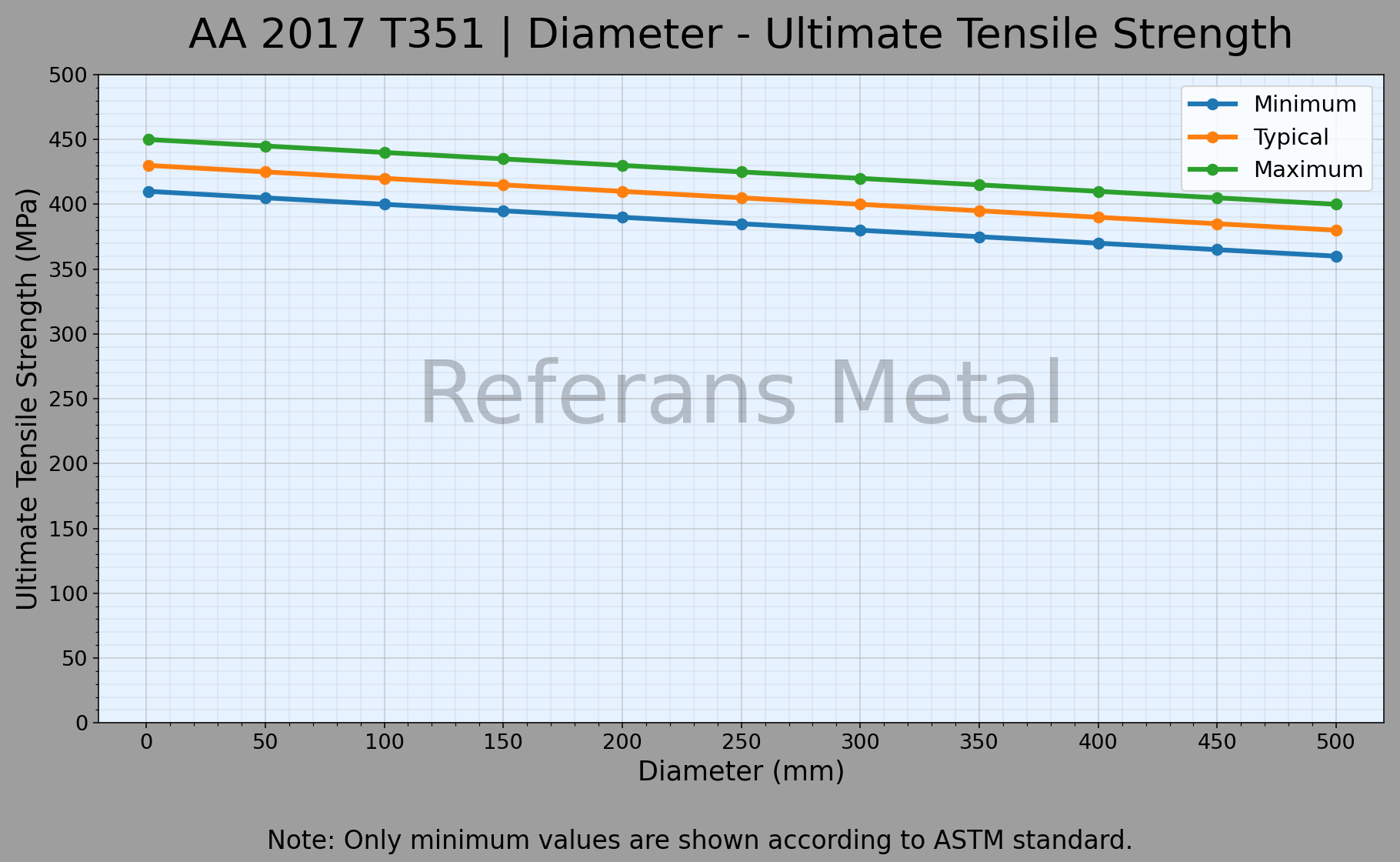

| 2017 T351 Diameter – Ultimate Tensile Strength Graph |

|

The cold-drawn 2017 T351 aluminum alloy is known for its high strength, good machinability, and fatigue resistance, and is frequently used in areas requiring high durability such as aerospace, automotive, and engineering. Thanks to its copper content, this alloy is well-suited for load-bearing and strength-critical components, providing long-lasting performance, especially in environments with intense vibration and impact. However, the high copper content limits its natural corrosion resistance; therefore, extra protective coating is required for use in open-air or marine environments. Its suitability for anodizing increases surface durability and corrosion resistance.

The weldability of the 2017 T351 aluminum alloy is limited; therefore, mechanical fastening methods are usually preferred in assembly. The cold-drawing process provides good bendability and high formability, even in complex shapes. Its high vibration resistance gives advantages in durability and performance in industries like automotive and aerospace. Advantages include high strength, fatigue resistance, good machinability, and anodizing compatibility, while disadvantages are low natural corrosion resistance and limited weldability. These characteristics make 2017 T351 aluminum alloy an ideal material for projects requiring durability and high performance.

MATERIAL COMPOSITION STANDARDS

2017 T351 is available according to the following standards:

• 2017 T351 Plate; AMS QQ-A-225/5, ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1, BS H14

• 2017 T351 Sheet; AMS QQ-A-225/5, ASTM B209, ISO AlCu4MgSi, UNS A92017, WNR 3.1325, DIN AlCuMg1, BS H14

• 2017 T351 Cold Drawn Round Bar; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316

• 2017 T351 Cold Drawn Tube; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316

• 2017 T351 Cold Drawn Flat Bar; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316

• 2017 T351 Cold Drawn Wire; AMS QQ-A-225/5, ASTM B211, UNS A92017, WNR 3.1325, DIN AlCuMg1, ASTM B565, ASTM B316

Key Properties of 2017 T351:

- Strength: Excellent

- Machinability: Very Good

- Weldability: Fair (Filler welding and brazing are preferred)

- Formability: Very Good

- Corrosion Resistance: Moderate (Improves with coating)

- Heat Treatable: Yes

Common Applications of 2017 T351:

Used as fasteners, rivets,

In aerospace industry as aircraft material,

In military equipment and other structural applications requiring high strength.

STOCK

We supply 2017 T351 in plate/sheet, sheet, rod/flat bar, and tube/profile forms.

- Plate / Sheet

- Sheet

- Rod / Flat Bar

- Tube / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 25 up to & incl. 75 | 270 MPa | 400 MPa | %10 |

| Over 75 up to & incl. 150 | 260 MPa | 390 MPa | %9 |

| Over 150 up to & incl. 200 | 240 MPa | 370 MPa | %8 |

| Over 200 up to & incl. 250 | 220 MPa | 360 MPa | %7 |

Weight Calculator

Weight Calculator