6063

ASTM B429 / AlMg0.7Si / 6063 / T52

| Chemical Properties | % Value |

| Silicon (Si) | 0,20 - 0,60 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 0,45 - 0,90 |

| Copper (Cu) | 0,00 - 0,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2,69 g/cm³ |

| Melting Point | 616 °C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 200 W/m.K |

| Electrical Resistivity | 53% IACS |

| Mechanical Properties | Value |

| Proof Strength | 140 MPa |

| Yield Strength | 180 MPa |

| Shear Strength | 100 MPa |

| Elongation A50 mm | 8% |

| Hardness | 65 HB |

The 6063 T52 aluminum alloy is known for its good mechanical strength, excellent machinability, and high corrosion resistance. The T52 temper represents a medium-strength form of the alloy, providing it with sufficient durability and flexibility. These properties make 6063 T52 ideal for a wide range of applications, including construction, automotive, aerospace, and outdoor structures. Additionally, 6063 T52 aluminum is suitable for anodizing, which enhances its surface appearance while increasing its corrosion resistance, making it suitable for long-term outdoor use.

In terms of weldability, 6063 T52 aluminum alloy can be easily welded. Its medium hardness makes the welding process straightforward, ensuring strong and reliable connections. However, proper heat treatment and welding techniques are necessary for optimal results. Regarding bending, 6063 T52 aluminum is easy to bend due to its medium hardness, making it suitable for various shaping processes and offering flexibility in applications.

The corrosion resistance of 6063 T52 is excellent, particularly in atmospheric conditions, and it provides good resistance to corrosive environments such as seawater. This makes it ideal for maritime and outdoor structural applications. Additionally, 6063 T52 aluminum alloy can be used in high-vibration environments, making it advantageous in industries such as automotive, aerospace, and defense. Its high durability and long-lasting performance further enhance its reliability in these dynamic applications.

The advantages of 6063 T52 aluminum alloy include high corrosion resistance, anodizing compatibility, weldability, and ease of bending. However, its medium hardness may not meet the requirements for applications that demand higher strength. Additionally, it may not be as durable as some harder alloys. Despite these limitations, 6063 T52 is an excellent choice for aesthetic applications and durable industrial use.

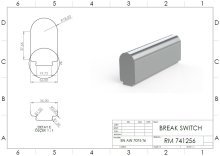

As Extruded Round/Flat Bar; 6063 T52, AMS QQ-A-200/9, ASTM B221 , ASTM B429, UNS A96063, DIN AlMgSi0,5

Choosing Factors for 6063 T52

- Strength: Average

- Machining: Good

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Excellent

- Heat Treating: Yes

Some Well-Known Applications for 6063 T52

Irrigation tubing

Structural cages and interior fittings

Doors, stair rails and also has a lot of applications in architecture.

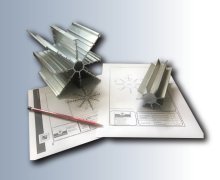

- Sheet

- Rod / Round Bar / Flat Bar

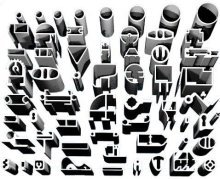

- Tube/Profile

Calculador de Peso

Calculador de Peso