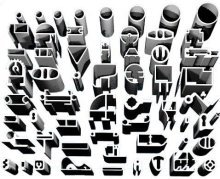

Plates

Sheets

Rod/Round Bar/Flat Bar

Tube/Extrusions/Profile

7075

QQ-A-250/24 / AlZn5.5MgCu / 7075 / T7651

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Tin (Sn) | 0,00 - 0,00 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Lead (Pb) | 0,00 - 0,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Nickel (Ni) | 0,00 - 0,00 |

| Aluminium (Al) | Balance |

| Titanium + Zirconium (Ti+Zr) | 0,00 - 0,25 |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 480 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 470 MPa |

| Yield Strength | 550 MPa |

| Shear Strength | 320 MPa |

| Elongation A50 mm | %8 |

| Hardness | 150 HB |

7075 T7651 aluminum alloy is recognized for its high strength and is frequently chosen in fields such as aerospace, defense, and automotive where reliability is paramount. After heat treatment, the T7651 condition imparts exceptional strength, hardness, and toughness, making it ideal not only for high-stress components but also in structural applications requiring a balance of lightness and robustness.

Its excellent strength-to-weight ratio has made 7075 T7651 popular in aircraft fuselages, wing flap assemblies, sports equipment, molds, and high-performance bicycle frames. The alloy is suitable for anodizing processes, thereby enhancing surface protection and aesthetics. However, its weldability can be more challenging compared to some other aluminum alloys, making mechanical fastening methods like riveting or bolting preferable in many cases.

Though its hardness is significant, 7075 T7651 can still be formed through cold bending to a certain degree. In environments characterized by high levels of vibration, it maintains its structural integrity and fatigue resistance, ensuring long-term durability. The alloy’s intrinsic corrosion resistance, further bolstered by proper surface treatments, helps it withstand harsh conditions such as salty or humid atmospheres.

On the downside, the material’s high hardness and strength may complicate machining operations like cutting, drilling, or milling, requiring specialized tools and techniques. Nevertheless, the combination of strength, lightness, durability, and anodizing capability for enhanced corrosion resistance makes 7075 T7651 an indispensable choice for numerous modern industrial applications.

Plate and Sheet as; 7075 T7651, AMS QQ-A-250/24,

ASTM B209, AIR 9048-710

Choosing Factors for 7075 T7651:

- Strength: Very good

- Machining: Excellent

- Weldability: Weak

- Formability: Poor

- Corrosion Resistance: Significant

- Heat Treating:Yes

TEMPER TYPES

AMS QQ-A-250/24 7075 is supplied in the following heat treatment types:

- T7651

Special Fuel Tanks

Ship industry

SUPPLIED FORMS

- Plate

- Sheet

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 12.7 up to & incl. 25.4 | 410 MPa | 486 MPa | 6 |

| over 6.35 up to & incl. 12.7 | 418 MPa | 491 MPa | 8 |

Weight Calculator

Weight Calculator