Листы/Плиты

Лист

Бар/Листовая Сталь

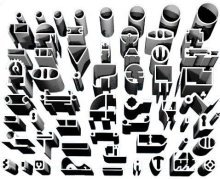

Трубы/Профили

1050

ASTM B211 / Al99.5 / 1050 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Manganese (Mn) | 0,00 - 0,05 |

| Magnesium (Mg) | 0,00 - 0,05 |

| Copper (Cu) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,03 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,05 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.705 g/cm³ |

| Melting Point | 646 °C |

| Thermal Expansion | 23.6 µm/m.°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | %40 IACS |

| Mechanical Properties | Value |

| Proof Strength | 28 MPa |

| Yield Strength | 78 MPa |

| Shear Strength | 62 MPa |

| Elongation A50 mm | %39 |

| Hardness | 21 |

1050 O aluminum alloy is part of the pure aluminum series, containing 99.5% pure aluminum. This alloy offers high formability, excellent corrosion resistance, and good electrical conductivity due to its soft and flexible nature. The O temper signifies that the material is annealed, making it very soft and easy to work with. These characteristics make it a popular choice for applications requiring low strength and lightweight structures.

1050 O aluminum is commonly used in kitchen utensils, chemical storage tanks, sheet metal works, and components for electrical equipment. It is suitable for anodizing, forming a smooth oxide layer that enhances both its aesthetic appeal and corrosion resistance. The alloy also demonstrates excellent weldability, allowing it to be joined easily with standard welding methods while retaining its structural integrity after welding.

In terms of bending and forming, 1050 O aluminum alloy is highly flexible and suitable for complex designs and precision forming processes. However, its low strength limits its application in high-vibration environments. It performs best in applications with light loads and low-stress conditions. While its fatigue resistance is relatively low, it provides long-lasting durability when used correctly.

Corrosion resistance is one of the most prominent advantages of 1050 O aluminum alloy. It exhibits excellent durability in humid, chemical, and marine environments. However, its low mechanical strength and limited performance in high-strength projects are notable drawbacks. Advantages include high formability, good weldability, and corrosion resistance, while disadvantages include low strength and limited fatigue resistance. These attributes make 1050 O an ideal material for applications requiring lightweight, durability, and easy machinability.

Choosing Factors for 1050 O

- Strength: Moderate

- Machining: Poor

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Very good

- Heat Treating: Yes

Some Well-Known Applications for 1050 O

It is used in chemical process plant equipment,

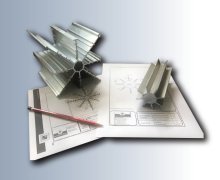

In heat sinks in the automotive industry,

It is also used in cable sheathing materials.

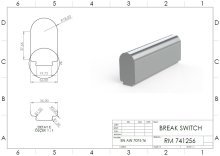

- Sheet

- Round/Flat Bar

- Tube/Profile

Калькулятор Веса

Калькулятор Веса