Cold Drawn Round Bar

Cold Drawn Tube

5052

Cold Drawn/Finished (CF) / AlMg2.5 (Soğuk Çekim) / 5052 / H14

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Chromium (Cr) | 0,15 - 0,35 |

| Manganese (Mn) | 0,00 - 0,10 |

| Magnesium (Mg) | 2,20 - 2,80 |

| Copper (Cu) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,40 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.68 g/cm³ |

| Melting Point | 607 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 140 W/m.K |

| Electrical Resistivity | %35 IACS |

| Mechanical Properties | Value |

| Proof Strength | 200 MPa |

| Yield Strength | 250 MPa |

| Shear Strength | 145 MPa |

| Elongation A50 mm | 11% |

| Hardness | 69 HB |

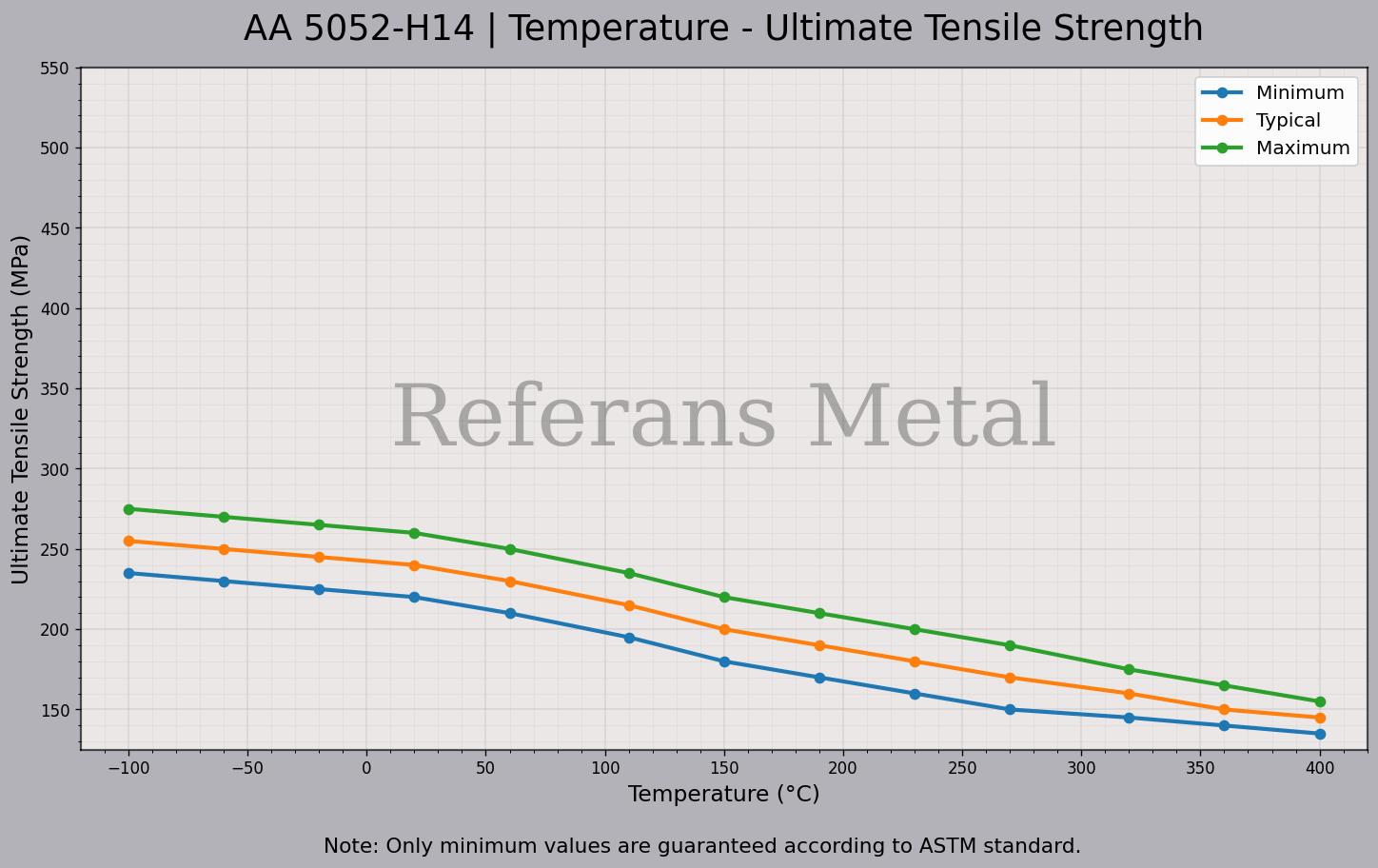

| 5052 H14 Temperature – Tensile Strength Graph |

|

The 5052 H14 cold drawn aluminum alloy is a material known for its high corrosion resistance, medium strength, and excellent formability. Widely used in the marine, automotive, and construction industries, 5052 H14 is especially ideal for applications exposed to moisture, seawater, and other harsh environmental conditions. It is also suitable for anodizing, which enhances surface hardness and aesthetics. This alloy is notable for its weldability and can be easily joined using both TIG and MIG welding methods.

Thanks to its high formability, the 5052 H14 alloy is extremely suitable for bending into complex parts. Cold drawing increases its strength, allowing it to be used in thinner and lighter structures. It also demonstrates good durability in vibrational environments, making it a preferred choice for vibrating applications and moving parts. Its advantages include high corrosion resistance, good weldability, and bendability, while its disadvantages include limited performance in applications requiring very high strength and moderate fatigue resistance. The 5052 H14 aluminum alloy is a reliable choice for projects where durability and formability are priorities.

MATERIAL COMPOSITION STANDARDS

5052 H14 can be produced according to the following standards:

• 5052 H14 Sheet; AMS QQ-A-250/8, ISO AlMg2.5, WNR 3.3523, UNS A95052, ASTM B209

• 5052 H14 Cold Drawn Round Bar; ASTM B211, ISO AlMg2.5, WNR 3.3523, WW-T-700/4, AMS QQ-A-225/7

• 5052 H14 Cold Drawn Bar; ASTM B211, ISO AlMg2.5, WNR 3.3523, WW-T-700/4, AMS QQ-A-225/7

• 5052 H14 Cold Drawn Wire; ASTM B211, ISO AlMg2.5, WNR 3.3523, WW-T-700/4, AMS QQ-A-225/7

• 5052 H14 Cold Drawn Tube; ASTM B210, ISO AlMg2.5, WNR 3.3523

Characteristic Properties of 5052 H14:

- Strength: Medium

- Machinability: Fair

- Weldability: Very Good

- Formability: Above Average

- Corrosion Resistance: Excellent

- Heat Treatable: No

Some Common Applications of 5052 H14:

Packaging materials and pallets,

Electronic circuits,

Also used in aviation industry fuel lines for aircraft.

STOCK

5052 H14 is supplied in sheet, rod/bar, and tube/profile forms.

- Tube/Profile

- Rod/Bar

- Sheet

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 234 | 283 | %3 |

| Over 0.5 up to & incl. 1.2 | 234 | 283 | %4 |

| Over 1.2 up to & incl. 2.9 | 234 | 283 | %6 |

Weight Calculator

Weight Calculator