Dalle

Tôle

Barre ronde

Tube/ Extrusion/ Profil

6005A

ASTM B211 / AlSiMg(A) / 6005A / T4

| Chemical Properties | % Value |

| Silicon (Si) | 0,50 - 0,90 |

| Chromium (Cr) | 0,00 - 0,30 |

| Manganese (Mn) | 0,00 - 0,50 |

| Magnesium (Mg) | 0,40 - 0,70 |

| Copper (Cu) | 0,00 - 0,30 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,20 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.63 g/cm³ |

| Melting Point | 582 °C |

| Thermal Expansion | 23.4 µm/m°C |

| Modulus of Elasticity | 69 GPa |

| Thermal Conductivity | 190 W/m.K |

| Electrical Resistivity | 49% IACS |

| Mechanical Properties | Value |

| Proof Strength | 100 MPa |

| Yield Strength | 200 MPa |

| Shear Strength | 120 MPa |

| Elongation A50 mm | %15 |

| Hardness | 69 GPa |

L’alliage d’aluminium 6005A T4 est reconnu pour sa haute résistance mécanique et son excellente résistance à la corrosion. Il est largement utilisé dans des secteurs tels que l’automobile, la construction et le transport, et est particulièrement privilégié pour les applications structurelles nécessitant une résistance élevée à la traction et une bonne dureté. De plus, le 6005A T4 est compatible avec l’anodisation ; ce procédé améliore la surface tant sur le plan esthétique que fonctionnel, tout en augmentant la résistance à la corrosion.

Cet alliage offre également une bonne soudabilité, ce qui en fait un choix idéal pour les processus de fabrication industrielle. Lorsqu’il est utilisé avec des techniques de soudage appropriées, il peut être soudé facilement et offre une grande flexibilité de production. En outre, l’alliage présente d’excellentes propriétés de pliage, une très bonne usinabilité et permet d’obtenir aisément les formes souhaitées lors du processus de mise en forme.

L’alliage d’aluminium 6005A T4 présente une résistance élevée à la corrosion, en particulier dans des environnements faiblement corrosifs. Bien qu’il offre de bonnes performances dans des conditions difficiles telles que les environnements marins, il peut subir certaines pertes de performance dans des milieux extrêmement agressifs. Par ailleurs, l’alliage convient à une utilisation dans des environnements à fortes vibrations ; cette caractéristique lui confère un avantage dans des secteurs tels que l’automobile et l’aéronautique, où la résistance aux vibrations est essentielle.

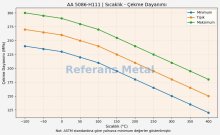

Parmi les avantages de l’alliage d’aluminium 6005A T4 figurent une haute résistance mécanique, une bonne résistance à la corrosion, la compatibilité avec l’anodisation, une bonne soudabilité et de bonnes propriétés de pliage. Cependant, il présente également certains inconvénients, tels qu’une diminution de la dureté à basse température et une résistance limitée dans des environnements fortement abrasifs. Malgré ces limitations, il constitue un choix idéal pour les applications nécessitant une intégrité structurelle et des performances fiables.

Le 6005A T4 peut être fourni conformément aux normes suivantes.

• 6005A T4 Barre étirée à froid; ISO AlSiMg(A), UNI 9006/6, DIN AlMgSi0.7, AFNOR A-GS0,5, UNE L-3454, WNR 3.3210, ASTM B211

• 6005A T4 Plat étiré à froid; ISO AlSiMg(A), UNI 9006/6, DIN AlMgSi0.7, AFNOR A-GS0,5, UNE L-3454, WNR 3.3210, ASTM B211

Facteurs de sélection pour le 6005A T4

- Résistance : Moyenne

- Usinabilité : Appropriée

- Soudabilité : Très bonne (le soudage à l’arc est le meilleur choix)

- Formabilité : Moyenne

- Résistance à la corrosion : Bonne

- Traitement thermique : Oui

Quelques applications courantes du 6005A T4

Utilisé comme poteaux et éléments de tours,

Conduites et tuyauteries,

Également utilisé dans des applications d’architecture intérieure.

Le 6005A T4 est produit et fourni sous forme de tôles/plaques, de barres/plats et de tubes/profilés.

- Barre / Barre ronde / Plat

- Tube / Profilé

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 0.2 up to & incl. 0.5 | 241 | 290 | %8 |

| Over 0.5 up to & incl. 6.5 | 241 | 290 | %10 |

Calculateur de Poids

Calculateur de Poids