Plates

Sheets

Rod/Round Bar/Flat Bar

Tube/Extrusions/Profile

7075

AMS 4078 / AlZn5.5MgCu / 7075 / T7351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477 °C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 435 MPa |

| Yield Strength | 510 MPa |

| Shear Strength | 300 MPa |

| Elongation A50 mm | 8% |

| Hardness | 135 HB |

In aviation and many other fields, 7075 T651 especially for large dimensions and high thicknesses has insufficient stress corrosion cracking resistance, which is why 7075

.png) T7351 is preferred. When used as large single-piece aluminum plates, selecting the appropriate AMS and ASTM standards allows 7075 T7351 to provide high resistance to stress corrosion while maintaining excellent dimensional tolerances and processability without warping.

T7351 is preferred. When used as large single-piece aluminum plates, selecting the appropriate AMS and ASTM standards allows 7075 T7351 to provide high resistance to stress corrosion while maintaining excellent dimensional tolerances and processability without warping.

Referans Metal imported this aluminum material to Turkey for the first time in 2006 using the Original Material Supply method and enabled its use in Turkey’s first space industry project.

7075 T7351 aluminum alloy is one of the most well-known high-strength aluminum alloys and is especially preferred in the aerospace and defense industries. Its main components are aluminum, zinc, magnesium, and copper; the high zinc content gives the alloy superior mechanical strength. The T7351 temper indicates that the material has undergone pre-stretching followed by solution heat treatment and aging; this process reduces internal stresses while increasing long-term durability. As a result, 7075 T7351 can be safely used in applications with critical load-bearing requirements.

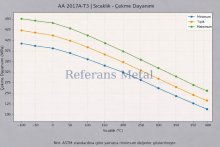

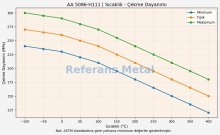

Mechanically, 7075 T7351 is quite impressive. Its tensile strength typically ranges between 500–560 MPa, while the yield strength is approximately 435 MPa. These values make it much stronger than most standard aluminum alloys, making it ideal for structural components requiring high strength. Additionally, the T7351 temper increases the material's fatigue resistance and fracture toughness; therefore, it is commonly used in aircraft fuselage parts, helicopter rotors, and high-performance vehicle chassis components.

Regarding machinability, 7075 T7351 has moderate workability. Machining processes require care because its high strength demands proper cutting tools and lower cutting speeds. The alloy is sensitive to welding, with a high risk of cracking during welding; therefore, mechanical fasteners or special brazing techniques are usually preferred over welding. Nevertheless, forging, milling, drilling, and surface treatments can be successfully performed with T7351.

In terms of corrosion resistance, 7075 T7351 may perform lower than some aluminum alloys due to its high zinc content. However, the T7351 temper allows a natural passive layer to form on the surface, and additional surface treatments like anodizing can significantly enhance corrosion resistance. These properties make it suitable for use in environments with harsh conditions, such as maritime and aerospace industries. Overall, 7075 T7351 stands out as an ideal alloy for engineering applications requiring high strength and durability.

MATERIAL COMPOSITION STANDARDS

7075 T7351 can be produced according to the following standards:

• 7075 T7351 Extrusion Round Bar; AMS QQ-A-200/11, AMS 4167, ASTM B221

• 7075 T7351 Extrusion Bar; AMS QQ-A-200/11, AMS 4167, ASTM B221

• 7075 T7351 Extrusion Wire; AMS QQ-A-200/11, AMS 4167, ASTM B221

• 7075 T7351 Sheet / Plate; AMS QQ-A-250/12, AMS 4078, ASTM B209, AIR 9048-690, WL 3.4364, ASTM B209, ABS5064, AMS QQ-A-250/12, LN 9073

• 7075 T7351 Cold Drawn Round Bar; AMS QQ-A-225/9, AMS 4124, ASTM B211

• 7075 T7351 Cold Drawn Bar; AMS QQ-A-225/9, AMS 4124, ASTM B211

• 7075 T7351 Cold Drawn Wire; AMS QQ-A-225/9, AMS 4124, ASTM B211

Characteristic Properties of 7075 T7351:

- Strength: Good

- Machinability: Normal

- Weldability: Poor

- Formability: Weak

- Corrosion Resistance: Significant

- Heat Treatable: Yes

Some Well-Known Applications of 7075 T7351:

Chassis manufacturing for medium-sized satellites

Long plates for thin-walled, hollow designs, fixture-rotary table projects

Connection fittings in aircraft

Coated valves and stems in the defense industry

STOCK

7075 T7351 is supplied in sheet/plate, rod, bar, and wire forms.

- Sheet / Plate

- Rod / Bar / Wire

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 6.35 up to & incl. 50.8 | 385 MPa | 468 MPa | 7 |

| over 50.8 up to & incl. 63.5 | 351 MPa | 448 MPa | 7 |

| over 63.5 up to & incl. 76.2 | 331 MPa | 434 MPa | 7 |

Weight Calculator

Weight Calculator