لوحات/ طباقات

صاج

قضيب

أنابيب

1060

AMS 4000 / Al99.6 / 1060 / O

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Manganese (Mn) | 0,00 - 0,03 |

| Magnesium (Mg) | 0,00 - 0,03 |

| Copper (Cu) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,03 |

| Iron (Fe) | 0,00 - 0,35 |

| Zinc (Zn) | 0,00 - 0,05 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.705 g/cm³ |

| Melting Point | 646 °C |

| Thermal Expansion | 22.8 µm/m°C |

| Modulus of Elasticity | 73 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | 62 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 21 MPa |

| Yield Strength | 75 MPa |

| Shear Strength | 49 MPa |

| Elongation A50 mm | 30% |

| Hardness | 19 HB |

سبائك الألمنيوم 1060 O تحتوي على 99.6% من الألمنيوم النقي، مما يوفر مقاومة ممتازة للتآكل، وتوصيل كهربائي رائع، وقابلية تشكّل فائقة. يشير التصلب O إلى أن السبيكة مختمرة (مُليّنة)، مما يعني أن لديها بنية ناعمة، مما يجعلها سهلة المعالجة ومثالية للعمليات الدقيقة للتشكيل. تُعد 1060 مناسبة بشكل أفضل للتطبيقات التي يتم فيها إعطاء الأولوية للقوة المنخفضة وخصائص مثل خفة الوزن وسهولة التشغيل.

تُستخدم هذه السبيكة عادة في المعدات الكيميائية، وأدوات المطبخ، وخطوط نقل الكهرباء، وأعمال الصفائح المعدنية، وخزانات التخزين. وهي متوافقة جدًا مع عملية التأكسد الأنودي، حيث تشكل طبقة أكسيدية ناعمة تعزز مقاومة التآكل وتوفر مظهرًا جذابًا. كما تتميز بقابلية ممتازة للّحام، مما يسمح بربطها بسهولة باستخدام تقنيات اللحام القياسية مع الحفاظ على متانتها بعد اللحام.

من حيث الثني والتشكيل، سبائك الألمنيوم 1060 O مرنة للغاية، مما يجعلها مناسبة للتصاميم المعقدة وعمليات الثني ذات نصف قطر ضيق. ومع ذلك، فإن قوتها المنخفضة تحد من استخدامها في البيئات عالية الاهتزاز أو المحملة ديناميكيًا. تؤدي بشكل استثنائي في التطبيقات ذات الأحمال الخفيفة والإجهاد المنخفض، وتتميز بمرونة عالية بسبب سهولة التشغيل الآلي لها.

تعد مقاومة التآكل واحدة من السمات البارزة لسبيكة 1060 O. فهي تظهر متانة رائعة في البيئات المسببة للتآكل مثل مياه البحر، والرطوبة، والتعرض للمواد الكيميائية. ومع ذلك، فإن قوتها الميكانيكية المنخفضة والملاءمة المحدودة للمشاريع عالية التحميل تعتبر من العيوب الملحوظة. تشمل ميزاتها العالية القابلية للتشكيل، وقابلية اللحام الممتازة، والمقاومة الفائقة للتآكل، بينما تشمل عيوبها القوة المنخفضة ومقاومة التعب المحدودة. تجعل هذه الخصائص من 1060 O خيارًا ممتازًا للمشاريع التي تتطلب خفة الوزن والمتانة وسهولة المعالجة.

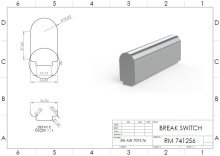

• 1060 O صفائح; ASTM B209,UNS A91060,ISO Al99.6,AMS 4000

• 1060 O قضيب دائري مبثوق; ASTM B221,ASTM B491,ISO Al99.6

• 1060 O شريط مسطح مبثوق; ASTM B221,ASTM B491,ISO Al99.6

• 1060 O سلك مبثوق; ASTM B221,ASTM B491,ISO Al99.6

• 1060 O أنبوب مبثوق; ASTM B221,ASTM B491,ISO Al99.6

• 1060 O قضيب دائري مسحوب على البارد; ASTM B211,ISO Al99.6

• 1060 O شريط مسطح مسحوب على البارد; ASTM B211,ISO Al99.6

• 1060 O سلك مسحوب على البارد; ASTM B211,ISO Al99.6

• 1060 O أنبوب مسحوب على البارد; ASTM B211,ISO Al99.6

عوامل اختيار 1060 O

- القوة: متوسطة

- التشغيل الآلي: ضعيف

- قابلية اللحام: ممتازة

- القابلية للتشكيل: مثالية

- مقاومة التآكل: جيدة جدًا

- المعالجة الحرارية: نعم

بعض التطبيقات المعروفة للـ 1060 O

يستخدم أيضًا في هياكل/ديكورات اللوحات الإعلانية،

أدوات المطبخ، الأدوات المنزلية

وكعنصر من عناصر السكك الحديدية.

- لوح

- أعمدة/قضبان مستديرة ومسطحة

- أنبوب/بروفيل

حساب الوزن

حساب الوزن