7075

BS L170 / AlZn5.5MgCu / 7075 / T6511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23 µm/m.°C |

| Modulus of Elasticity | 71.7 GPa |

| Thermal Conductivity | 130 W/m.K |

| Electrical Resistivity | %33 IACS |

| Mechanical Properties | Value |

| Proof Strength | 515 MPa |

| Yield Strength | 580 MPa |

| Shear Strength | 340 MPa |

| Elongation A50 mm | 11% |

| Hardness | 155 HB |

7075 T6511 aluminum alloys are highly preferred in rod form. They are also used in tube form, but for tight tolerances, seamless extrusion is preferred. Although it is similar to 7075 T6, a straightening process is applied for certain tolerance values after heat treatment. Due to its excellent hard anodize coating properties, the production of aluminum tubes/profiles/rods provides significant advantages in terms of cost and lead time. Both the straightening process and stress relief make 7075 T6511 highly preferred because of its price.

Referans Metal supplies 7075 T6511 in tube, rod, or custom-designed profile forms according to ASTM B210, ASTM B241, ASTM B221, and ASTM B211 standards. For best delivery times and pricing, be sure to call us.

7075 T6511 is a high-strength alloy widely used in structural applications. Its main components are aluminum, zinc, magnesium, and copper. The T6511 designation indicates that the material has undergone solution treatment and aging, with stresses relieved to enhance dimensional stability. Compared to T651, T6511 is usually produced with tighter tolerances and more controlled stress relief, making it ideal for precision engineering parts..png)

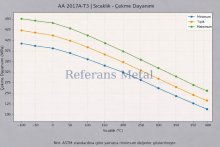

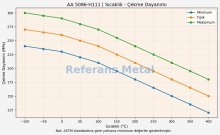

In terms of strength, 7075 T6511 is very high. Tensile strength typically ranges from 572–640 MPa, with a yield strength of about 503 MPa. This high strength makes the alloy suitable for structural components in aerospace, defense, and high-performance automotive sectors, particularly aircraft fuselages, landing gear, helicopter rotor components, and precision machinery parts. Its high fatigue resistance ensures reliable performance under repeated and long-term loads.

In terms of machinability, 7075 T6511 is moderate due to its high strength. Turning, milling, and drilling can be applied, but attention must be paid to heat buildup and proper cutting tools must be used. Welding is generally not recommended, as the high zinc and copper content can cause cracking during welding. Therefore, mechanical joining methods (such as bolts or rivets) are a safer option.

In terms of corrosion resistance, 7075 T6511 is moderate. Its high zinc content makes it sensitive to corrosion, especially in humid or salty environments. Therefore, surface anodizing or protective coating is often required. With these measures, 7075 T6511 provides both high strength and reliable corrosion resistance, making it ideal for durable and precise structural components.

MATERIAL COMPOSITION STANDARDS

7075 T6511 alloys are available according to the following standards:

• 7075 T6511 Extrusion Tube; AMS 4168, AMS 4169 (special straightening), AMS QQ-A-200/11, EN 2394, EN 2631, ASTM B221

• 7075 T6511 Extrusion Profile; AMS 4168, AMS 4169 (special straightening), AMS QQ-A-200/11, EN 2394, EN 2631, ASTM B221

• 7075 T6511 Extrusion Round Bar; AMS 4168, AMS 4169 (special straightening), AMS QQ-A-200/11, EN 2394, EN 2631, ASTM B221

• 7075 T6511 Extrusion Bar; AMS 4168, AMS 4169 (special straightening), AMS QQ-A-200/11, EN 2394, EN 2631, ASTM B221

• 7075 T6511 Seamless Tube; AMS 4169, AMS QQ-A-200/11, ASTM B221

• 7075 T6511 Seamless Profile; AMS 4169, AMS QQ-A-200/11, ASTM B221

Characteristic Properties of 7075 T6511:

- Strength: Excellent

- Machinability: Notable

- Weldability: Poor

- Formability: Moderate

- Corrosion Resistance: Poor

- Heat Treatment: Yes

Some Well-Known Applications of 7075 T6511:

Almost every industry requiring high strength and precision gears or mechanisms.

Especially in aerospace for load-bearing equipment connections.

Also used in mountaineering, furniture, and kitchen industries.

STOCK

7075 T6511 is supplied in rod/bar, tube/profile, or extrusion form.

- Rod / Bar

- Tube / Profile / Extrusion

Weight Calculator

Weight Calculator