5005

ASTM B209 / AlMg1 / 5005 / H34

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,30 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,50 - 1,10 |

| Copper (Cu) | 5,80 - 6,80 |

| Iron (Fe) | 0,00 - 0,70 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.70 g/cm³ |

| Melting Point | 632 °C |

| Thermal Expansion | 23.8 µm/m.°C |

| Modulus of Elasticity | 68 GPa |

| Thermal Conductivity | 200 W/m.K |

| Electrical Resistivity | 52% IACS |

| 机械性能 | 值 |

| Proof Strength | 138 MPa |

| Yield Strength | 160 MPa |

| Shear Strength | 96 MPa |

| Elongation A50 mm | 7% |

| Hardness | 41 HB |

The 5005 H34 aluminum alloy is known for its good corrosion resistance, medium mechanical strength, and excellent machinability. The H34 temper represents a semi-hardened form of the alloy, providing it with sufficient strength and formability. These characteristics make 5005 H34 ideal for applications in industries such as construction, automotive, marine, and outdoor structures. Additionally, 5005 H34 aluminum is suitable for anodizing, which enhances its surface appearance while increasing its corrosion resistance, making it perfect for long-term outdoor use.

In terms of weldability, 5005 H34 aluminum alloy can be successfully welded. Its semi-hardened structure makes the welding process easier and ensures strong, reliable welds. However, proper heat treatment and welding techniques are important to achieve the best results. Regarding bending, 5005 H34 aluminum is easy to bend due to its medium hardness, making it suitable for a variety of shaping processes and providing flexibility in applications.

The corrosion resistance of 5005 H34 is excellent, especially in atmospheric conditions, and it provides good resistance to corrosive environments such as seawater. This makes it ideal for marine and outdoor structural applications. Additionally, 5005 H34 aluminum alloy can be used in high-vibration environments, making it advantageous in industries such as automotive, aerospace, and defense.

The advantages of 5005 H34 aluminum alloy include good corrosion resistance, anodizing compatibility, weldability, and ease of bending. However, its mechanical strength is not as high as some other alloys, which may limit its use in heavy-duty applications. Additionally, it may not meet the requirements for high durability in certain applications. Despite these limitations, 5005 H34 is an excellent choice for lightweight structures, aesthetic applications, and industrial environments that require corrosion resistance.

Sheets per; 5005 H34, ISO AlMg1, DIN AlMg1, WNR 3.3315, UNS A95005, ASTM B209, BS N41

Cold Drawn Round/Flat Bar per; 5005 H34, ISO AlMg1, DIN AlMg1, WNR 3.3315, UNS A95005, ASTM B211

Cold Drawn Tubes per; 5005 H34, ISO AlMg1, DIN AlMg1, WNR 3.3315, UNS A95005, ASTM B210

Choosing Factors for 5005 H34

- Strength: Medium

- Machining: Fair

- Weldability: Very good

- Formability: Good

- Corrosion Resistance: Perfect

- Heat Treating: None

Some Well-Known Applications for 5005 H34

In anodized parts,

Traffic and road signs and signage in general,

Also used in architectural applications.

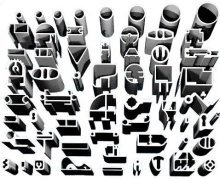

SUPPLIED FORMS

- Sheet

- Round/Flat Bar

- Tube/Profile

计算 重量计算

计算 重量计算