Plates

Sheets

Rod/Round Bar/Flat Bar

Tube/Extrusions/Profile

2618A

ASTM B211 / AlCu2Mg1.5Ni / 2618A / T6511

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,25 |

| Tin (Sn) | 0,00 - 0,05 |

| Manganese (Mn) | 0,00 - 0,20 |

| Magnesium (Mg) | 1,20 - 1,80 |

| Copper (Cu) | 1,80 - 2,70 |

| Lead (Pb) | 0,00 - 0,05 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,90 - 1,40 |

| Zinc (Zn) | 0,00 - 0,15 |

| Nickel (Ni) | 0,80 - 1,40 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.76 g/cm³ |

| Melting Point | 535 °C |

| Thermal Expansion | 21.6 µm/m°C |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 147 W/m.K |

| Electrical Resistivity | 36 % IACS |

| Mechanical Properties | Value |

| Proof Strength | 372 MPa |

| Yield Strength | 441 MPa |

| Shear Strength | 262 MPa |

| Elongation A50 mm | 10% |

| Hardness | 115 HB |

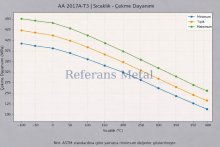

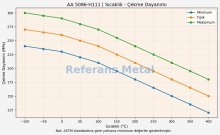

2618A T6511 aluminum alloy is a material distinguished by its superior thermal stability, high strength, and fatigue resistance. This alloy consists of copper, magnesium, and silicon elements, making it an ideal choice for applications requiring high temperature resistance and mechanical load capacity. The T6511 temper indicates that the alloy has undergone solution heat treatment followed by stress relief and natural aging processes, which provide the material with excellent durability and dimensional stability.

This alloy is especially used for critical components in aerospace, automotive, and defense industries. It is frequently preferred for jet engine parts, aircraft structures, engine pistons, and components resistant to high temperatures. 2618A T6511 is compatible with anodizing and can increase corrosion resistance by forming a protective oxide layer on the surface. However, due to the alloy's high copper content, careful application is required during the anodizing process. This alloy has limitations in weldability, and mechanical joints or special welding techniques are usually preferred.

In terms of forming and bending, 2618A T6511 aluminum alloy offers limited formability due to its high strength. Complex forming processes can be challenging but successful results can be achieved with appropriate techniques and careful handling. The alloy shows excellent performance in environments exposed to high vibration and dynamic loads due to its fatigue resistance and mechanical stability. This characteristic makes it ideal for applications requiring durability and long service life.

Corrosion resistance is moderate and additional surface protection processes are recommended, especially in humid or abrasive environments. Its advantages include high temperature resistance, fatigue resistance, and mechanical stability, while its disadvantages include low weldability, limited formability, and moderate corrosion resistance. These properties make 2618A T6511 aluminum alloy an excellent choice for projects requiring lightness and high durability.

MATERIAL COMPOSITION STANDARDS

2618A T6511 can be produced according to the following standards:

• 2618A T6511 Extrusion Round Bar; ASTM B221, UNS A92618, AIR 9048.150, ISO AlCu2Mg1.5Ni, WNR 3.1924, DTD 5014A

• 2618A T6511 Extrusion Plate; ASTM B221, UNS A92618, AIR 9048.150, ISO AlCu2Mg1.5Ni, WNR 3.1924, DTD 5014A

• 2618A T6511 Extrusion Wire; ASTM B221, UNS A92618, AIR 9048.150, ISO AlCu2Mg1.5Ni, WNR 3.1924, DTD 5014A

• 2618A T6511 Extrusion Tube; ASTM B221, UNS A92618, AIR 9048.150, ISO AlCu2Mg1.5Ni, WNR 3.1924, DTD 5014A

• 2618A T6511 Cold Drawn Round Bar; ASTM B211, UNS A92618, ISO AlCu2Mg1.5Ni, WNR 3.1924, EN 3553

• 2618A T6511 Cold Drawn Plate; ASTM B211, UNS A92618, ISO AlCu2Mg1.5Ni, WNR 3.1924, EN 3553

• 2618A T6511 Cold Drawn Wire; ASTM B211, UNS A92618, ISO AlCu2Mg1.5Ni, WNR 3.1924, EN 3553

• 2618A T6511 Cold Drawn Tube; ASTM B211, UNS A92618, ISO AlCu2Mg1.5Ni, WNR 3.1924, EN 3553

Characteristic Properties of 2618A T6511:

- Strength: High

- Machinability: Reasonable

- Weldability: Poor

- Formability: Good

- Corrosion Resistance: Moderate

- Heat Treatment: Yes

Some Well-Known Applications for 2618A T6511:

Aircraft engines and fuselages, high-tech industry applications, and automobile pistons.

STOCK

We produce and supply 2618A T6511 in rod, plate, tube, and profile forms.

- Rod / Plate

- Tube / Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Up to & incl. 10 | Min 320 MPa | Min 400 MPa | %5 |

| Over 10 mm up to & incl. 100 mm | Min 340 MPa | Min 420 MPa | 5% |

Weight Calculator

Weight Calculator