Листы/Плиты

Лист

Бар/Листовая Сталь

Трубы/Профили

2219

AMS 4313 / AlCu6Mn / 2219 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.85 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 116 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 248 MPa |

| Yield Strength | 359 MPa |

| Shear Strength | 230 MPa |

| Elongation A50 mm | 13% |

| Hardness | 100 HB |

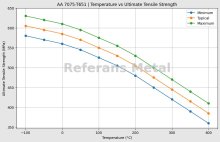

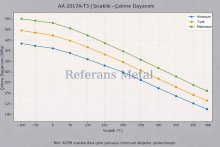

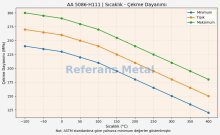

Алюминиевый сплав 2219 T351 известен своей высокой прочностью, исключительной термостойкостью и хорошей обрабатываемостью. Его медное содержание обеспечивает сплаву отличную механическую прочность и сопротивление усталости, а обозначение термообработки T351 означает, что сплав прошёл термическую обработку раствором, снятие напряжений и естественное старение для достижения стабильности. Эти характеристики делают его идеальным материалом для работы в условиях высоких температур и интенсивных нагрузок.

Этот сплав широко используется в аэрокосмической и оборонной промышленности, а также в ответственных конструкциях. Его применяют в конструкциях фюзеляжей самолётов, топливных баках и космических аппаратах, где важны высокая прочность и термостойкость. 2219 T351 подходит для анодирования, формируя защитный оксидный слой для улучшения коррозионной стойкости, хотя из-за содержания меди требуется осторожное применение. Свариваемость отличная, особенно методами TIG и MIG, что делает сплав пригодным для различных сварных конструкций.

Что касается гибки и формовки, алюминиевый сплав 2219 T351 обладает средней формуемостью. Его высокая прочность может усложнять выполнение сложных формовочных операций, но при правильных методах можно добиться успешных результатов. Сплав обладает хорошей сопротивляемостью усталости и механической стабильностью, что делает его надёжным выбором для сред с высокой вибрацией и конструкций, испытывающих динамические нагрузки.

Коррозионная стойкость ограничена, особенно в условиях высоких температур и агрессивных химических сред, поэтому для наружного применения рекомендуется дополнительная защита или покрытия. Преимущества этого сплава включают высокую прочность, термостойкость, отличную свариваемость и сопротивляемость усталости, а недостатки — ограниченную коррозионную стойкость и сниженные формовочные свойства. Эти характеристики делают алюминиевый сплав 2219 T351 отличным материалом для проектов, требующих долговечности и высокой производительности.

ОБОЗНАЧЕНИЯ СПЛАВА

ФАКТОРЫ ВЫБОРА ДЛЯ 2219 T351

- Прочность: Очень хорошая

- Обрабатываемость: Плохая

- Свариваемость: Отличная

- Формуемость: Хорошая

- Коррозионная стойкость: Удовлетворительная

- Термообработка: Да

Некоторые известные применения 2219 T351

В конструкциях с высокой прочностью сварных соединений,

В топливных баках и авиационных материалах,

Используется в инженерных приложениях и преимущественно в аэрокосмической отрасли.

2219 T351 производится/поставляется в виде пластин/листов, круглых/плоских прутков и труб/профилей.

- Круглый пруток / Пруток / Плоский пруток

- Плита/Лист

- Труба/Профиль

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 6.3 up to & incl. 25.4 | 317 MPa | 427 MPa | %8 |

| Over 25,4 up to & incl. 50,8 | 317 MPa | 427 MPa | %7 |

Калькулятор Веса

Калькулятор Веса