Platos

Hojas

Barras Circulares

Tubos / Extrusion / Perfil

2219

AMS 4313 / AlCu6Mn / 2219 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.85 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 116 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 248 MPa |

| Yield Strength | 359 MPa |

| Shear Strength | 230 MPa |

| Elongation A50 mm | 13% |

| Hardness | 100 HB |

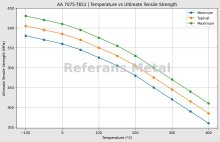

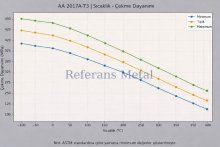

La aleación de aluminio 2219 T351 es conocida por su alta resistencia, excepcional estabilidad térmica y buena maquinabilidad. Su composición rica en cobre proporciona a la aleación una excelente resistencia mecánica y a la fatiga, mientras que el temple T351 indica que ha pasado por un tratamiento térmico de solución, alivio de tensiones y envejecimiento natural para lograr estabilidad. Estas características la hacen un material ideal para condiciones operativas exigentes y de alta temperatura.

Esta aleación se utiliza ampliamente en las industrias aeroespacial y de defensa, así como en aplicaciones estructurales críticas. Se emplea comúnmente en fuselajes de aviones, tanques de combustible y vehículos espaciales, donde la alta resistencia y estabilidad térmica son esenciales. 2219 T351 es adecuada para anodizado, formando una capa protectora de óxido para mejorar la resistencia a la corrosión, aunque su contenido de cobre requiere una aplicación cuidadosa. Su soldabilidad es excelente, particularmente con métodos de soldadura TIG y MIG, lo que la hace altamente adecuada para una amplia gama de estructuras soldadas.

En términos de doblado y conformado, la aleación de aluminio 2219 T351 ofrece una formabilidad moderada. Su alta resistencia puede dificultar procesos de conformado complejos, pero con las técnicas correctas se pueden lograr resultados exitosos. Su resistencia a la fatiga y estabilidad mecánica la convierten en una opción fiable para entornos con alta vibración y estructuras sometidas a cargas dinámicas.

La resistencia a la corrosión es naturalmente limitada, especialmente en ambientes de alta temperatura y químicos, por lo que se recomiendan tratamientos o recubrimientos adicionales para uso en exteriores. Las ventajas de esta aleación incluyen alta resistencia, estabilidad térmica, excelente soldabilidad y resistencia a la fatiga, mientras que sus desventajas son resistencia limitada a la corrosión y menor formabilidad. Estas características hacen que la aleación de aluminio 2219 T351 sea un material excelente para proyectos que requieren durabilidad y alto rendimiento.

DESIGNACIONES DE ALEACIÓN

Factores de Selección para 2219 T351

- Resistencia: Muy buena

- Mecanizado: Bajo

- Soldabilidad: Excelente

- Formabilidad: Buena

- Resistencia a la corrosión: Satisfactoria

- Tratamiento térmico: Sí

Algunas aplicaciones conocidas para 2219 T351

En estructuras soldadas de alta resistencia,

En tanques de combustible y materiales para aeronaves,

Se utiliza en aplicaciones de ingeniería y generalmente en el sector aeroespacial.

2219 T351 se produce/suministra en formas de placa/lamina, barra redonda/plana y tubo/perfil.

- Barra redonda / Barra redonda / Barra plana

- Placa/Lámina

- Tubo/Perfil

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 6.3 up to & incl. 25.4 | 317 MPa | 427 MPa | %8 |

| Over 25,4 up to & incl. 50,8 | 317 MPa | 427 MPa | %7 |

Calculador de Peso

Calculador de Peso