Plates

Sheets

Rod/Round Bar/Flat Bar

Tube/Extrusions/Profile

2219

AMS 4313 / AlCu6Mn / 2219 / T351

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.85 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 116 W/m.K |

| Electrical Resistivity | 30% IACS |

| Mechanical Properties | Value |

| Proof Strength | 248 MPa |

| Yield Strength | 359 MPa |

| Shear Strength | 230 MPa |

| Elongation A50 mm | 13% |

| Hardness | 100 HB |

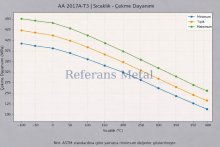

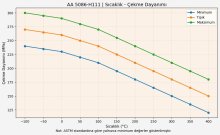

2219 T351 aluminum alloy is known for its high strength, exceptional thermal stability, and good machinability. Its copper-rich composition provides the alloy with excellent mechanical strength and fatigue resistance, while the T351 temper signifies that it has undergone solution heat treatment, stress relief, and natural aging to achieve stability. These characteristics make it an ideal material for high-temperature and demanding operational conditions.

This alloy is widely used in the aerospace and defense industries and for critical structural applications. It is commonly employed in aircraft fuselages, fuel tanks, and space vehicles, where high strength and thermal stability are essential. 2219 T351 is suitable for anodizing, forming a protective oxide layer to improve corrosion resistance, though its copper content necessitates careful application. Its weldability is excellent, particularly with TIG and MIG welding methods, making it highly suitable for a wide range of welded structures.

In terms of bending and forming, 2219 T351 aluminum alloy offers moderate formability. Its high strength can make complex forming processes challenging, but with the correct techniques, successful results can be achieved. Its fatigue resistance and mechanical stability make it a reliable choice for high-vibration environments and structures subjected to dynamic loads.

Corrosion resistance is naturally limited, especially in high-temperature and chemical environments, so additional protection treatments or coatings are recommended for outdoor use. Advantages of this alloy include high strength, thermal stability, excellent weldability, and fatigue resistance, while its disadvantages include limited corrosion resistance and reduced formability. These attributes make 2219 T351 aluminum alloy an excellent material for projects requiring durability and high performance.

ALLOY DESIGNATIONS

Choosing Factors for 2219 T351

- Strength: Very good

- Machining: Poor

- Weldability: Great

- Formability: Good

- Corrosion Resistance: Satisfactory

- Heat Treating: Yes

Some Well-Known Applications for 2219 T351

In high strength weldaments,

In fuel tanks and aircraft materials,

It is used in engineering applications and generally in the aerospace sector.

2219 T351 is produced/supplied in plate/sheet, round/flat bar and tube/profile forms.

- Rod / Round Bar / Flat Bar

- Plate/Sheet

- Tube/Profile

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| Over 6.3 up to & incl. 25.4 | 317 MPa | 427 MPa | %8 |

| Over 25,4 up to & incl. 50,8 | 317 MPa | 427 MPa | %7 |

Weight Calculator

Weight Calculator