板/板

钣金

棒条/金属板

管道/型材

2219

AMS 4313 / AlCu6Mn / 2219 / T351

| 化学性质 | % 值 |

| Silicon (Si) | 0,00 - 0,20 |

| Manganese (Mn) | 0,20 - 0,40 |

| Magnesium (Mg) | 0,00 - 0,02 |

| Copper (Cu) | 5,80 - 6,80 |

| Titanium (Ti) | 0,02 - 0,10 |

| Iron (Fe) | 0,00 - 0,30 |

| Zinc (Zn) | 0,00 - 0,10 |

| Aluminium (Al) | Balance |

| 物理特性 | 值 |

| Density | 2.85 g/cm³ |

| Melting Point | 543 °C |

| Thermal Expansion | 22.3 µm/m.°C |

| Modulus of Elasticity | 74 GPa |

| Thermal Conductivity | 116 W/m.K |

| Electrical Resistivity | 30% IACS |

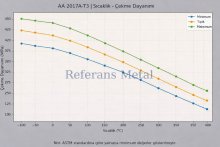

| 机械性能 | 值 |

| Proof Strength | 248 MPa |

| Yield Strength | 359 MPa |

| Shear Strength | 230 MPa |

| Elongation A50 mm | 13% |

| Hardness | 100 HB |

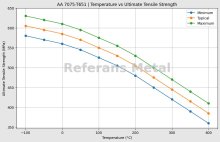

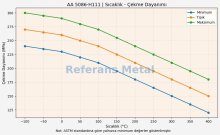

2219 T351 铝合金 以其高强度、卓越的热稳定性和良好的加工性能而闻名。其富含铜的成分赋予该合金出色的机械强度和抗疲劳性能,而 T351 状态表示经过固溶处理、应力消除和自然时效以实现稳定性。这些特性使其成为高温和苛刻操作条件下的理想材料。

该合金广泛应用于航空航天和国防工业以及关键结构应用中。它通常用于飞机机身、燃油箱和航天器中,在这些领域高强度和热稳定性至关重要。2219 T351 适合阳极氧化,形成保护性氧化层以提高耐腐蚀性,但其铜含量需要谨慎应用。其焊接性能优异,尤其适用于 TIG 和 MIG 焊接方法,非常适合各种焊接结构。

在弯曲和成型方面,2219 T351 铝合金 具有中等的成形性。其高强度可能使复杂成型工艺具有挑战性,但采用正确技术可以取得成功。其抗疲劳性能和机械稳定性使其成为高振动环境和承受动态载荷结构的可靠选择。

耐腐蚀性自然有限,尤其是在高温和化学环境中,因此户外使用建议采取额外的保护处理或涂层。该合金的优点包括高强度、热稳定性、优良的焊接性能和抗疲劳性能,缺点包括耐腐蚀性有限和成形性降低。这些特性使2219 T351 铝合金 成为需要耐用性和高性能项目的优良材料。

合金规格

2219 T351 选择因素

- 强度: 非常好

- 加工性能: 差

- 焊接性能: 极佳

- 成形性: 良好

- 耐腐蚀性: 满意

- 热处理: 是

2219 T351 的一些知名应用

用于高强度焊接件,

用于燃油箱和飞机材料,

用于工程应用,通常在航空航天领域。

2219 T351 以板材/薄板、圆棒/扁条和管材/型材形式生产供应。

- 棒材 / 圆棒 / 扁条

- 板材/薄板

- 管材/型材

| 机械性能 | |||

| 厚度 (mm) | 证明力量 (Min.) | 屈服强度 (Min.) | Uzama % |

| Over 6.3 up to & incl. 25.4 | 317 MPa | 427 MPa | %8 |

| Over 25,4 up to & incl. 50,8 | 317 MPa | 427 MPa | %7 |

计算 重量计算

计算 重量计算