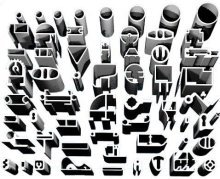

Plates

Sheets

Rod/Round Bar/Flat Bar

Tube/Extrusions/Profile

7075

ASTM B221 / AlZn5.5MgCu / 7075 / T7

| Chemical Properties | % Value |

| Silicon (Si) | 0,00 - 0,40 |

| Chromium (Cr) | 0,18 - 0,28 |

| Manganese (Mn) | 0,00 - 0,30 |

| Magnesium (Mg) | 2,10 - 2,90 |

| Copper (Cu) | 1,20 - 2,00 |

| Titanium (Ti) | 0,00 - 0,20 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 5,10 - 6,10 |

| Aluminium (Al) | Balance |

| Physical Properties | Value |

| Density | 2.81 g/cm³ |

| Melting Point | 477°C |

| Thermal Expansion | 23.4 µm/m.°C |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 155 W/m.K |

| Electrical Resistivity | 33% IACS |

| Mechanical Properties | Value |

| Proof Strength | 435 MPa |

| Yield Strength | 505 MPa |

| Shear Strength | 290 MPa |

| Elongation A50 mm | 13% |

| Hardness | 130 HB |

7075 T7 aluminum alloy is one of the most well-known and widely preferred high-strength aluminum alloys. As a zinc-based alloy, 7075 is strengthened with alloying elements such as magnesium and copper. Thanks to the T7 heat treatment temper, its strength is increased while also improving its resistance to stress corrosion cracking. With these properties, it is especially preferred in the aerospace, defense, and automotive industries where lightweight and high strength are simultaneously required.

Although it has high tensile and yield strength, its weldability is limited; therefore, it is generally used in designs where machinability and mechanical properties are prioritized. At the same time, due to its high surface hardness and wear resistance, it is also widely used in mold making, sports equipment, marine applications, and high-performance engineering parts. The 7075 T7 alloy stands out in critical engineering solutions by offering steel-like strength values together with the lightweight advantage of aluminum.

ALLOY DESIGNATIONS

7075 T7 can conform to the following standards.

As extruded bar/flat bar, wire, and tube; 7075 T7, ASTM B221, AMS 4166, AMS QQ-A-200/11

DTD 5124

Choosing Factors for 7075 T7:

- Strength: High

- Machinability: Medium

- Weldability: Low

- Formability: Poor

- Corrosion Resistance: Quite good

- Heat Treatment: Yes

Some Well-Known Applications for 7075 T7:

In high-performance sports equipment,

It is used in racing car parts.

SUPPLIED FORMS

7075 T7 is supplied/pro in the form of tube, bar, and extrusion.

- Tube / Bar / Extrusion

| Mechanical Properties | |||

| Thickness (mm) | Proof Strength (Min.) | Yield Strength (Min.) | Elongation A50 mm % |

| over 6.35 up to & incl. 50.8 | 389 MPa | 472 MPa | 6.0 - 7.0 |

| over 50.8 up to & incl. 63.5 | 355 MPa | 451 MPa | 6 |

| over 63.5 up to & incl. 76.2 | 334 MPa | 437 MPa | 6 |

Weight Calculator

Weight Calculator