Cold Drawn Round Bar

Cold Drawn Tube

6012

Cold Drawn/Finished (CF) / AlMgSiPb (Soğuk Çekim) / 6012 / T6

| Chemical Properties | % Value |

| Silicon (Si) | 0,60 - 1,40 |

| Chromium (Cr) | 0,00 - 0,10 |

| Manganese (Mn) | 0,40 - 1,00 |

| Magnesium (Mg) | 0,60 - 1,20 |

| Copper (Cu) | 0,60 - 1,10 |

| Titanium (Ti) | 0,00 - 0,10 |

| Iron (Fe) | 0,00 - 0,50 |

| Zinc (Zn) | 0,00 - 0,25 |

| Aluminium (Al) | Balance |

| Lead (Pb) | 0,40 - 2,00 |

| Physical Properties | Value |

| Density | 2,72 g/cm³ |

| Melting Point | 579 °C |

| Thermal Expansion | 21.7 µm/m-°C |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 150 W/m.K |

| Electrical Resistivity | %38 IACS |

| Mechanical Properties | Value |

| Proof Strength | 260 MPa |

| Yield Strength | 320 MPa |

| Shear Strength | 190 MPa |

| Elongation A50 mm | 9% |

| Hardness | 120 HB |

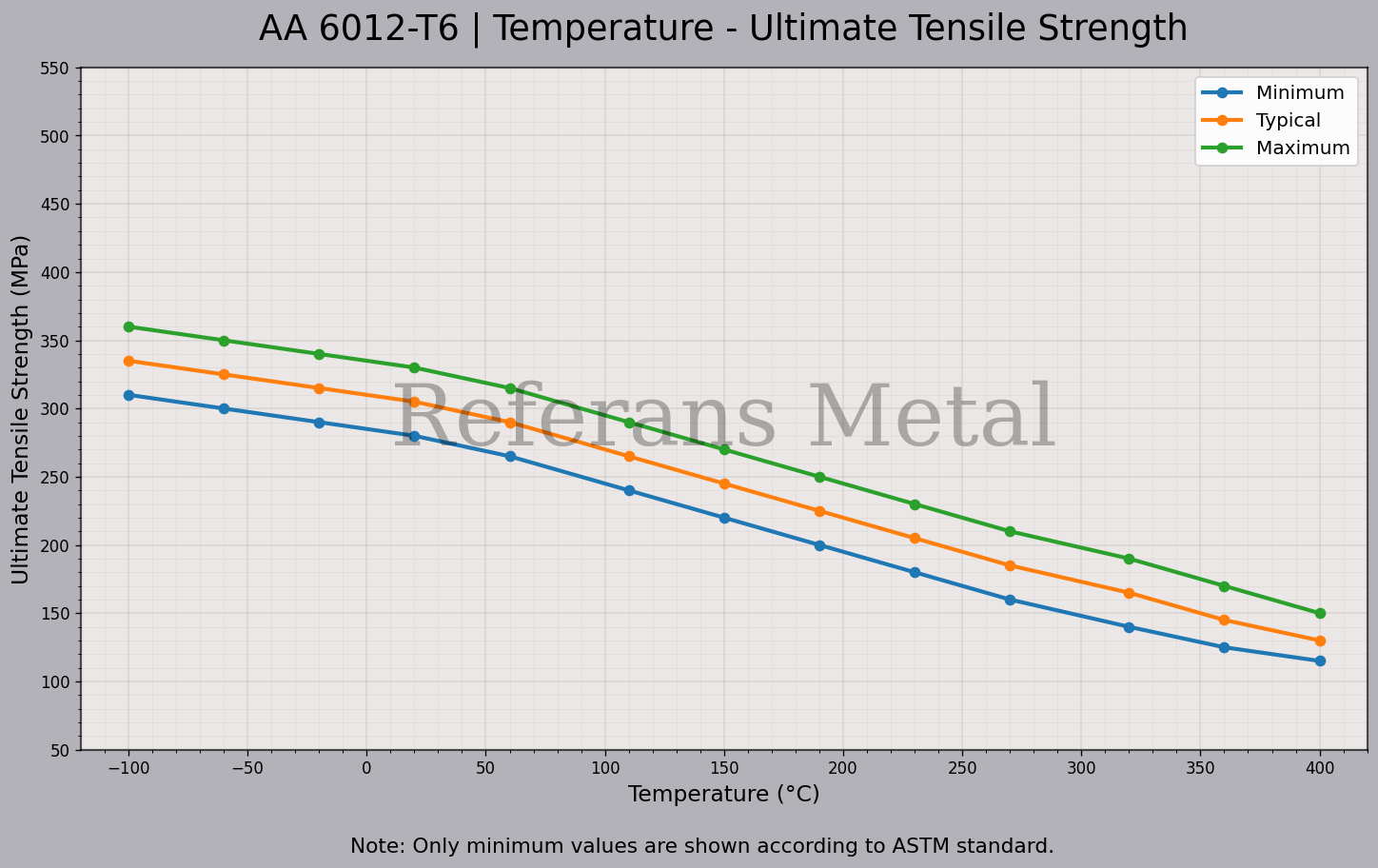

| 6012 T6 Temperature – Tensile Strength Graph |

|

6012 T6 aluminum alloy is a material belonging to the 6000 series aluminum-magnesium-silicon (Al-Mg-Si) group of alloys. This alloy is particularly known for offering high strength together with good corrosion resistance. Its chemical composition typically includes 0.6–1.2% silicon (Si) and 0.3–0.6% magnesium (Mg); it also contains small amounts of trace elements such as copper (Cu), iron (Fe), manganese (Mn), and chromium (Cr). This composition provides 6012 T6 with a high strength-to-weight ratio, making it a preferred lightweight yet strong structural material in the automotive, aerospace, and machinery industries.

In terms of mechanical properties, 6012 T6 exhibits quite high strength in the T6 temper (solution heat-treated and artificially aged). Typically, its tensile strength ranges between 310–350 MPa, while its yield strength is around 270–310 MPa. Elongation is approximately 10–12%, indicating that the material has sufficient ductility and a low risk of cracking under impact or bending. Thanks to these properties, 6012 T6 can be safely used in structural parts and durable engineering components that require high strength.

In terms of machinability, 6012 T6 performs well, similar to other 6000 series alloys. It is suitable for machining processes such as CNC machining, milling, drilling, and cutting; however, when machining in hard tempers like T6, the use of appropriate cutting tools and parameters is recommended. The alloy also has good weldability; high-quality and durable joints can be achieved using MIG and TIG welding methods. Nevertheless, since mechanical properties may change due to the heat-affected zone after welding, precautions should be taken for critical parts.

In terms of corrosion resistance, 6012 T6 is highly resistant, especially to atmospheric and marine environments. The thin and dense natural oxide layer formed on its surface acts as a protective barrier against rusting and general corrosion. However, if use is planned in chloride-containing environments such as seawater or in aggressive chemical conditions, additional protection through anodizing or suitable coating processes is recommended.

Thanks to these properties, 6012 T6 aluminum alloy is widely used in automotive chassis and body parts, aerospace components, machine constructions, profile and tube extrusions, sports and recreational equipment, as well as durable structural and engineering applications. Its light weight, high strength, good corrosion resistance, and machinability make it an ideal material for modern industrial design and manufacturing processes.

STANDARDS FOR MATERIAL COMPOSITION

6012 T6 can be available in the following standards.

• 6012 T6 Cold Drawn Bar; UNS A96012, ASTM B211, ISO AlMgSiPb, WNR 3.0615

Characteristic Properties of 6012 T6:

- Strength: Medium-High

- Machinability: Good

- Weldability: Good

- Formability: Notable

- Corrosion Resistance: Very Good

- Heat Treatable: Yes

Some Well-Known Applications for 6012 T6:

Specially machined parts,

Automotive brake system components,

Hydraulic valves.

STOCK

We manufacture/supply 6012 T6 in bar form.

- Bar

Weight Calculator

Weight Calculator